Value Engineering Services

Reduce Manufacturing Costs Without Compromising Quality

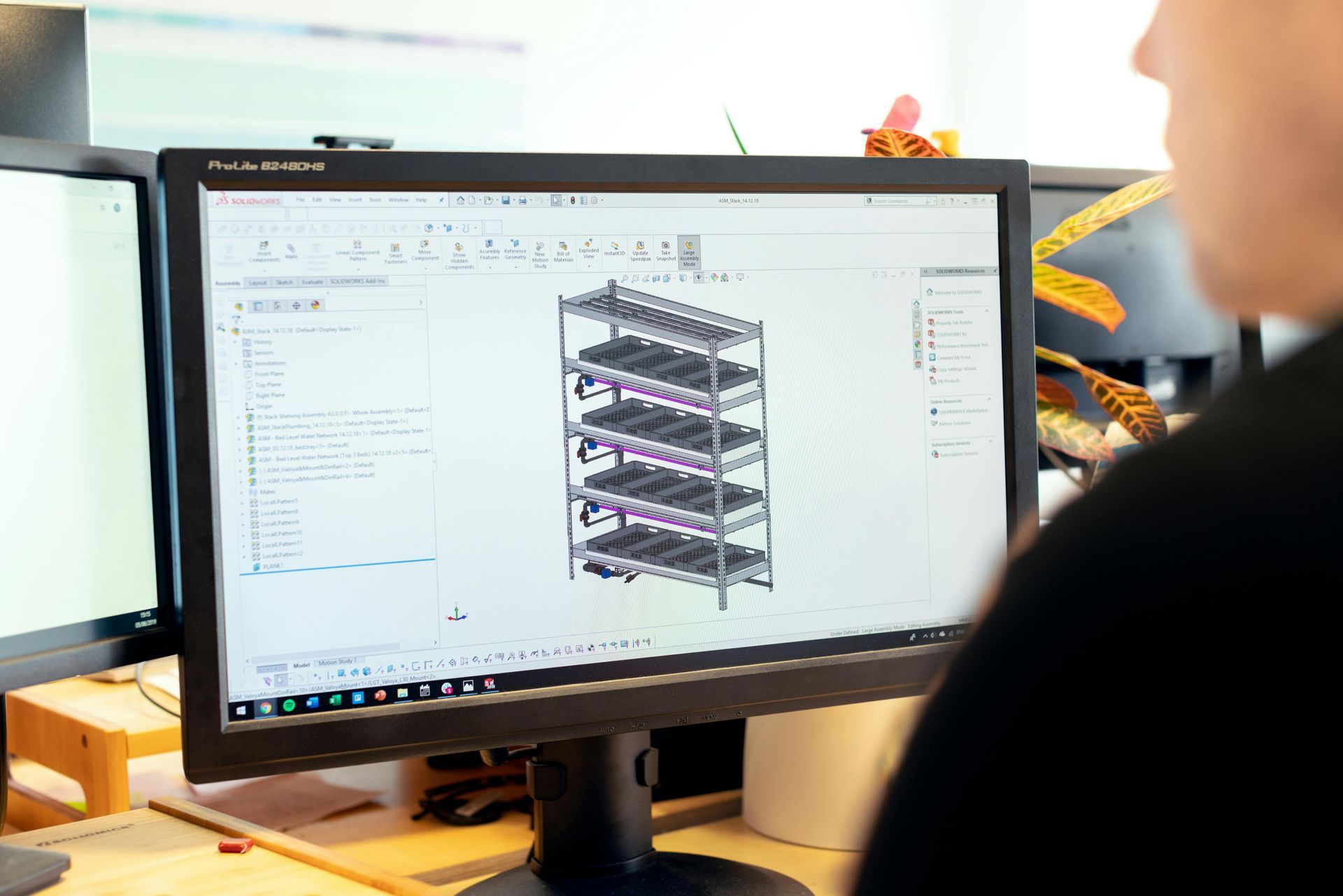

When manufacturing budgets demand efficiency, Pearse Bertram's value engineering services deliver the analysis and optimization needed to reduce costs while maintaining performance standards. Our engineers bring 70+ years of manufacturing knowledge to every project, examining your designs and bill of materials to identify cost-effective alternatives that preserve fit, form, and function.

We evaluate every component in your design to recommend alternatives that improve your bottom line without sacrificing quality. Our systematic approach to component optimization has helped clients reduce manufacturing costs by 15-30% while maintaining technical specifications.

Comprehensive Bill of Materials Analysis

Our value engineering services start with a thorough bill of materials analysis examining every component for cost reduction opportunities. We leverage extensive supplier relationships and deep knowledge of industrial components to identify functionally equivalent alternatives that deliver the same performance at lower cost.

The analysis extends beyond component substitution. Our engineers evaluate your entire assembly for manufacturing efficiency, examining how choices affect production time, assembly complexity, and quality control. We consider component availability, lead times, and supplier reliability to ensure cost reductions translate into operational benefits rather than supply chain challenges.

We work with your existing designs regardless of origin. Whether developed in-house or inherited from another source, we analyze your bill of materials and recommend improvements aligned with your manufacturing goals at any product lifecycle stage.

Ask an Expert

Have questions about how value engineering services could reduce your manufacturing costs? Our experienced engineers are ready to discuss your specific requirements and evaluate cost optimization opportunities.

Proactive Design Assistance for Cost-Effective Manufacturing

Value engineering delivers greatest impact during the design phase, before tooling investments lock in costly approaches. Our engineers provide proactive design assistance incorporating cost considerations from the beginning, helping you make informed decisions about component selection, manufacturing methods, and assembly strategies.

We bring manufacturing expertise to your design process, offering insights about how component choices affect assembly time, quality control, and production efficiency. Our team identifies design elements that create unnecessary costs or complicate production, helping you avoid expensive redesigns.

The collaborative approach extends to material selection and specification refinement. We evaluate whether tighter tolerances or premium materials truly benefit your application or simply increase costs. Our engineers recommend standard components that meet technical requirements at lower cost than custom specifications.

Engineering Consultation and Technical Problem Solving

Our value engineering services include engineering consultation addressing technical questions and manufacturing challenges. We function as an extension of your engineering department, providing specialized knowledge in automation components, assembly methods, and manufacturing processes.

We review current production methods to identify opportunities for process improvements, equipment upgrades, or workflow optimization that reduce operating costs. Our engineers evaluate whether changes in component suppliers, manufacturing techniques, or quality control approaches could improve operational efficiency.

Manufacturing cost reduction requires balancing component costs, production efficiency, quality standards, and supply chain reliability. Our engineers provide data-driven recommendations supporting informed decision-making, explaining technical implications of different approaches and their effect on total cost of ownership.

Component Selection Expertise Across Multiple Industries

Our value engineering capabilities draw on experience across medical devices, defense contracting, food and beverage processing, and industrial automation. This broad industry knowledge allows us to identify component solutions and manufacturing approaches that might not be obvious within single industry contexts.

Component selection considers industry-specific requirements and regulatory standards affecting your operations. We understand pharmaceutical applications demand different quality documentation than industrial equipment, and defense contracting involves specific compliance requirements. Our recommendations account for these factors, ensuring cost reductions don't compromise regulatory compliance.

We maintain relationships with more than 60 industrial suppliers, providing access to comprehensive component ranges and market intelligence for favorable pricing opportunities. This supplier network allows recommendations based on current availability, pricing trends, and quality performance.

Manufacturing Process Optimization

Value engineering extends beyond component selection to manufacturing process optimization reducing production costs through improved efficiency. Our engineers analyze assembly procedures to identify opportunities for streamlining operations, reducing handling time, or eliminating unnecessary steps.

Process optimization considers your existing manufacturing capabilities and operational constraints. We recommend improvements implementable with current equipment and workforce rather than requiring major capital investments, allowing you to realize cost reductions without disrupting established operations.

Our team evaluates how component choices affect downstream manufacturing including quality inspection, testing procedures, and final assembly. We identify situations where slightly higher component costs enable significant savings in assembly time or testing requirements.

Quality Assurance and Performance Verification

Cost reduction recommendations maintain rigorous quality standards protecting product performance and customer satisfaction. We verify proposed component alternatives meet technical specifications through careful evaluation of manufacturer data sheets, industry certifications, and performance testing. Our less than 0.5% return rate due to workmanship demonstrates that cost reduction and quality excellence are complementary goals.

Verification includes evaluation of component reliability, expected service life, and failure modes to ensure alternative components deliver the same operational performance as original specifications. We consider environmental factors, operating conditions, and stress levels to confirm proposed alternatives perform reliably in your specific application.

Our engineers document technical rationale behind recommended changes, providing engineering justification needed to evaluate proposals and make informed decisions. We explain how alternative components meet specifications and describe any performance characteristic differences.

Supply Chain Management and Component Sourcing

Our value engineering services include supply chain management support addressing component availability, lead times, and supplier reliability. We evaluate proposed alternatives for cost, performance, supply chain stability, and procurement efficiency. For any customer fabrication service that Pearse Betram+ cannot handle in-house (e.g. anodizing, molding, 3D printing, PCBs), we have a list of vetted specialists we can leverage for comparative quotes on your product.

Sourcing expertise extends to strategic inventory management and volume purchasing opportunities. As both an industrial distributor and contract manufacturer, we leverage purchasing power to negotiate favorable component pricing. We maintain more than $3 million in local inventory, supporting production schedules with immediate component availability.

Our team monitors market conditions and component lifecycle status to alert you to potential obsolescence issues or supply constraints before they impact production operations. This proactive supply chain management helps avoid costly delays and allows planning for component transitions with adequate preparation time.

Request for Quote

Submit your bill of materials for complimentary value engineering analysis. We'll identify cost reduction opportunities and provide detailed recommendations for improving manufacturing efficiency.