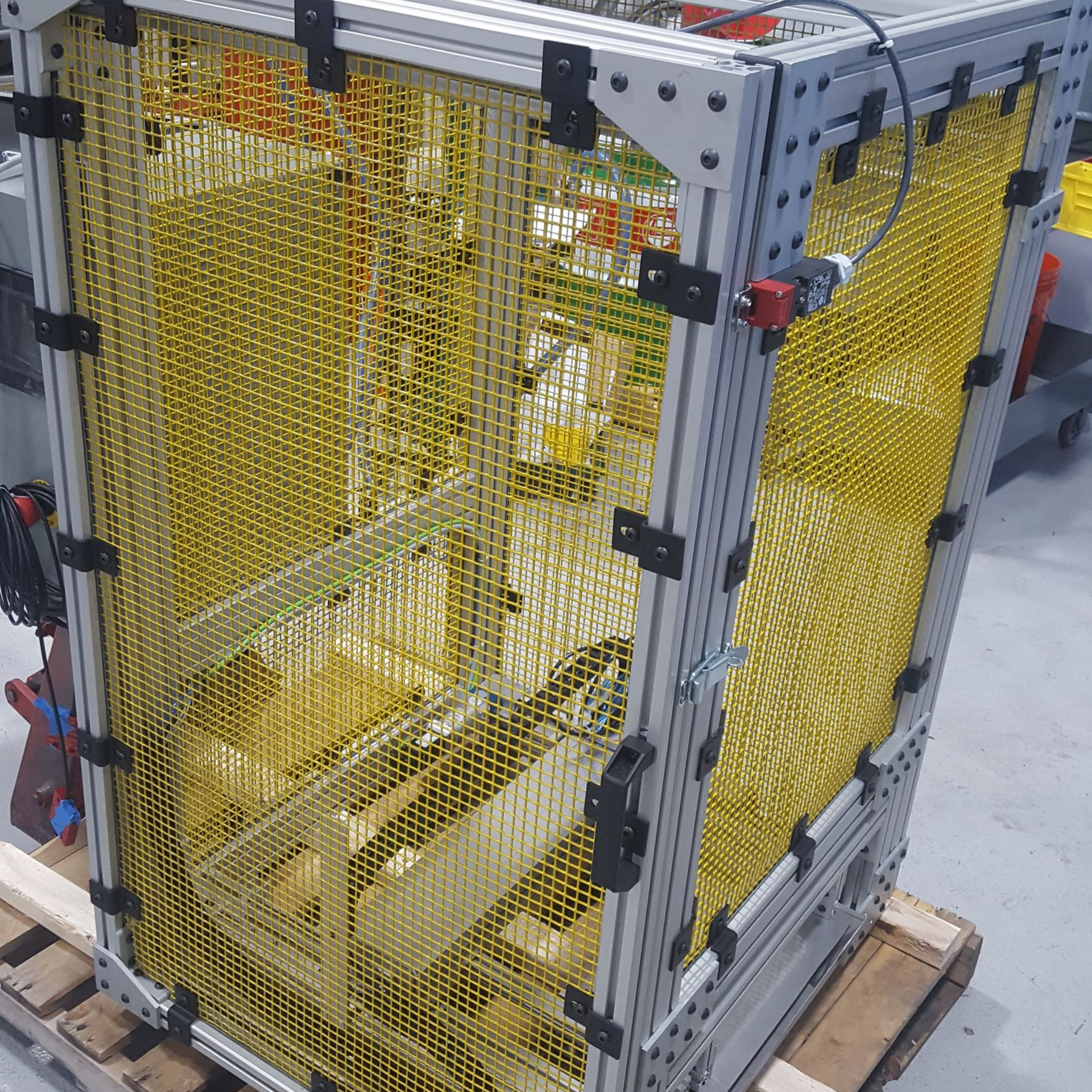

Turnkey OEM Machine Assembly and Build Services

Streamline Contract Manufacturing builds complete turnkey OEM machines from prototype through production, handling everything from component sourcing to final testing and delivery. Our dual role as both an industrial distributor and contract manufacturer eliminates the middleman markup, typically saving customers 20-30% compared to traditional contract manufacturers.

We build machines for virtually every industry including medical devices, life sciences equipment, food and beverage processing, defense systems, test and measurement equipment, industrial automation, and more. Whether you need a single prototype or volume production, our engineers work directly with your team to manufacture quality machines that meet specifications the first time.

Ask an Expert

Our engineers understand the challenges of bringing OEM equipment from design to production. Let's discuss your machine specifications and determine how our turnkey manufacturing capabilities can reduce your costs and accelerate your time to market.

How Our Dual Business Model Works For You

As both an established industrial distributor and contract manufacturer, we avoid the supply chain challenges and markup pricing that affect traditional contract manufacturers. We purchase components at wholesale through our distribution relationships with over 100 manufacturers, then pass those savings directly to you.

This means the same machine assembly costs 20-30% less from us versus other contract manufacturers who must buy components through distributors at marked-up prices. We stock $3-4 million in inventory, providing buffer against supply chain disruptions without requiring you to carry component inventory.

Our engineering team evaluates your bill of materials for free, identifying drop-in equivalent components that reduce costs without compromising functionality. Customers typically save 15-30% off bottom-line costs by partnering with a company that handles both distribution and manufacturing.

Certifications and Standards

Our facility maintains certifications that support quality manufacturing:

ISO 9001:2015 certified by TRNA

UL 508A certified for industrial control panel fabrication

EPTAC IPC certified for electronic assembly and soldering

ESD-safe workstations for handling sensitive electronic components

These certifications demonstrate systematic quality management and technical competence in critical manufacturing disciplines.

Who We Build For

We work with established companies like Amazon, Thermo Fisher, and General Dynamics, as well as startups launching their first products. Project scope doesn't determine service quality; every customer receives thorough consultation and engineering support.

Startup companies benefit from our ability to handle the complete manufacturing process, enabling them to focus on product development and sales rather than building manufacturing infrastructure. We've helped companies launch products that wouldn't have been commercially viable without our value engineering and volume purchasing power.

Established manufacturers use our services to handle overflow production, manufacture specialized products outside their core capabilities, or reduce total cost of ownership by outsourcing assembly operations.

Getting Started

We begin with a consultation to understand your machine specifications, production volumes, and delivery requirements. Our engineering team reviews your drawings and BOM, identifying potential issues and cost reduction opportunities.

After value engineering your design, we provide a detailed quote covering component costs, assembly labor, testing requirements, and delivery schedule. Once you approve the quote, we source components, develop assembly procedures, and build your first units with appropriate engineering oversight. We document the process and refine procedures based on what we learn during initial production.

FAQs

What is a turnkey machine solution?

A turnkey machine solution is an assembly that can function as a complete product as opposed to a subassembly. This often includes electro-mechanical assembly, software programming, component procurement, testing, packaging, and delivery. You receive a fully functional, tested system ready for delivery.

What types of turnkey machines do you build?

We design and build custom assemblies for Warehouse Automation & Robotics, Life Science, Biotechnology, and Medical Devices, Industrial Machinery, Building Automation, Aerospace and Defense, Semiconductor Equipment, Pharmaceutical, Food and Beverage, and Chemical, Water and Wastewater treatment. We have built complete machines like blood processing machines, bioreactors, glue fillers, strain testers, mobile robot test stations, hydraulic test stands, and more.

How long does it take to design and build a custom turnkey machine?

Project timelines vary significantly based on complexity and the long-lead item required for your build. Simple automation equipment may require 4-6 weeks, while complex integrated systems can take 6-12 months. Our engineering team provides detailed project schedules during the proposal phase, breaking down design, procurement, fabrication, and testing timeframes. We can make suggestions for alternative parts to pull in lead time.

Do you provide installation and startup support?

In general, we do not spearhead onsite installation or wire machinery. However, our engineers are happy to provide on-site installation support, system commissioning support, operator training, and performance validation. We remain involved through successful production ramp-up to ensure your equipment performs as designed.

Can you integrate with our existing equipment and systems?

Absolutely. Our engineers specialize in integrating new automation equipment with existing production lines, SCADA systems, and manufacturing execution systems. We ensure seamless communication and coordinated operation across your facility.

What happens if we need modifications during the process or after delivery?

Mid-stream changes and engineering revisions are welcome. Please keep in mind that they may slow the process or lead to additional costs. We provide ongoing support including system modifications, capacity upgrades, and additional functionality integration. Our engineers work with you to implement changes that enhance performance or adapt to new production requirements. Pearse Bertram does not believe in tribal knowledge; all revisions and changes must be documented and approved.

Do you provide spare parts and maintenance support?

If a product requires routine maintenance, troubleshooting, or you need technical support after delivery, Pearse Bertram is happy to provide that information free of charge. We can also suggest maintenance/spare parts and schedules, and create operation manuals for your team. In general, Pearse Bertram personnel do not provide routine service or maintenance. We are also not in the business of doing general repairs, rebuilds, wiring, or installation. However, we have a network of colleagues that we can point you to for those kinds of services.

Request for Quote

Send us your machine drawings, BOM, and production requirements. We'll evaluate your design for value engineering opportunities and provide a complete quote for turnkey manufacturing services.