Safety Audits & Compliance Assessment Services

Manufacturing safety requirements continue to evolve, placing increasing responsibility on facility managers and safety coordinators to maintain compliant operations while protecting workers from preventable hazards. Pearse Bertram's safety audits provide the comprehensive evaluation and actionable recommendations your facility needs to identify compliance gaps, reduce injury risks, and implement effective safety improvements that satisfy OSHA requirements.

Our team of experienced engineers brings 70+ years of industrial automation expertise to every safety assessment, evaluating your equipment, procedures, and protective systems with the technical depth that only comes from decades of hands-on manufacturing experience. We understand that effective machine safety evaluation requires more than checkbox compliance—it demands practical knowledge of how equipment operates, where hazards actually occur, and which solutions will perform reliably in your specific production environment.

Whether you need a comprehensive facility-wide safety audit or targeted assessment of individual machines, our engineers provide the technical insight and product knowledge necessary to address safety concerns efficiently and cost-effectively. We work with you to develop practical improvement plans that enhance worker protection while minimizing operational disruption and controlling implementation costs.

Comprehensive Facility Safety Assessments

Our facility safety audits examine every aspect of your manufacturing operation where worker safety intersects with equipment operation and material handling. Engineers conduct thorough on-site evaluations that identify potential hazards, assess existing protective measures, and document compliance status against current OSHA standards and industry best practices.

The evaluation process addresses machine guarding adequacy, lockout-tagout procedures, emergency stop accessibility, and the proper implementation of safety interlocks and protective devices. We examine electrical control panels for proper labeling and arc flash protection, review pneumatic and hydraulic systems for pressure relief and containment measures, and evaluate robotic work cells for appropriate safeguarding and operator protection.

Our engineers pay particular attention to areas where machinery modifications or production changes may have created new hazards not addressed by original equipment safeguards. We document findings with photographs and detailed notes that provide clear evidence of safety concerns and support your improvement planning efforts. This documentation proves valuable both for internal safety meetings and for demonstrating due diligence to regulatory inspectors.

Following the on-site assessment, we provide a comprehensive report that prioritizes safety concerns based on hazard severity and regulatory compliance requirements. Our recommendations include specific corrective actions, suggested safety products, and estimated implementation timelines that help you address critical issues promptly while planning longer-term improvements within budget constraints.

Ask an Expert

Have questions about your facility's safety compliance or need guidance on machine guarding requirements? Our experienced engineers are ready to discuss your specific safety concerns and recommend practical solutions that protect your workers while meeting OSHA standards.

Machine-Specific Safety Evaluations

Individual machine safety evaluations focus on specific equipment where safety concerns have been identified or where production changes require updated safeguarding. Our engineers assess machine guarding effectiveness, operator exposure to moving parts, and the adequacy of emergency stop systems for the actual operating conditions in your facility.

These targeted evaluations prove particularly valuable when purchasing used equipment, modifying existing machinery, or investigating near-miss incidents that suggest inadequate protection. We examine mechanical hazards, electrical safety concerns, and operator interface design to identify specific improvements that will reduce injury risk while maintaining production efficiency.

Machine safety assessments include:

Industrial Safety Product Selection and Implementation

After completing your safety audit, our engineers work with you to select appropriate safety products that address identified hazards while fitting your operational requirements and budget constraints. We represent globally recognized manufacturers whose safety components meet OSHA standards and provide the reliability your facility demands.

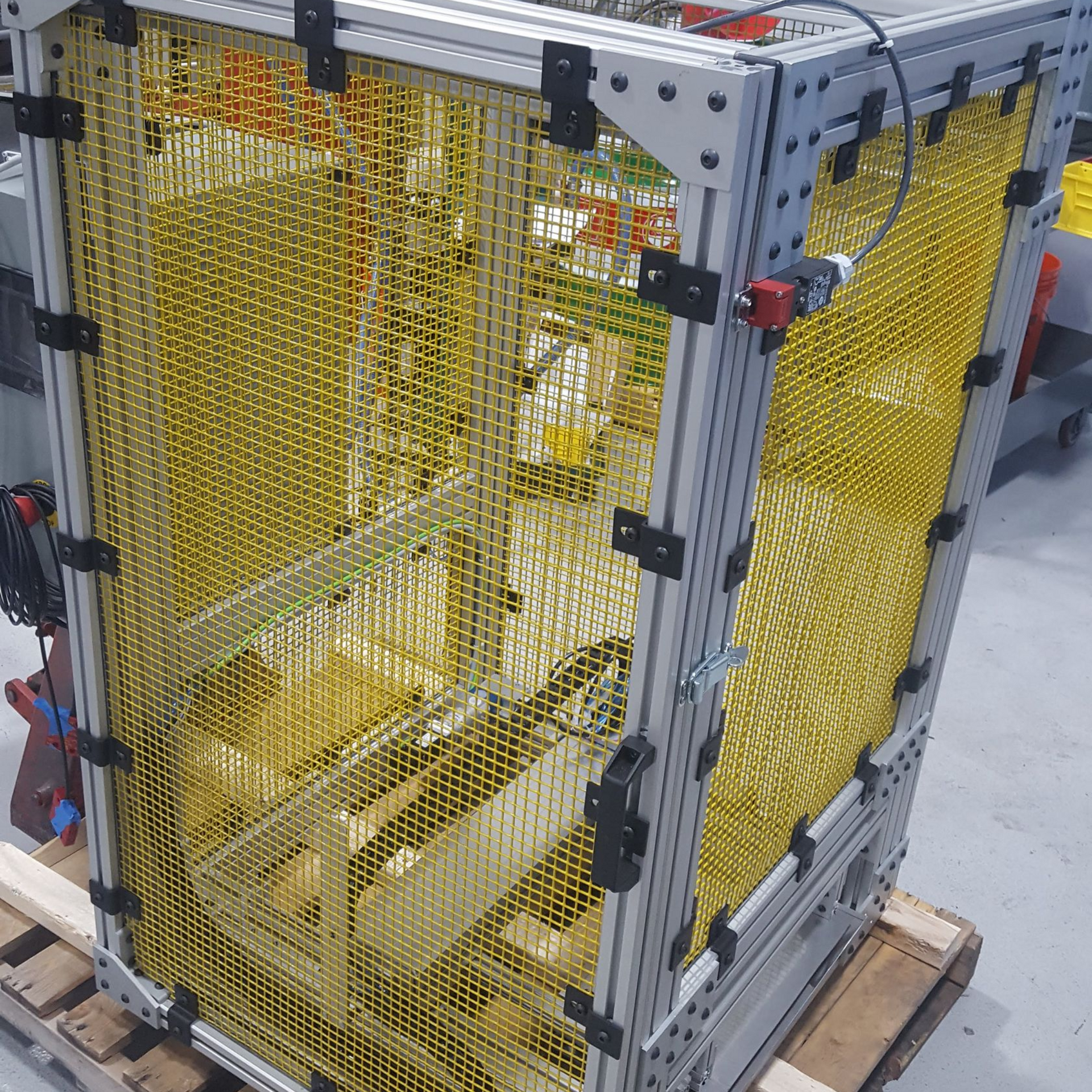

Our safety product portfolio includes light curtains for point-of-operation protection, laser scanners for area safeguarding, and safety mats for access control applications. We provide safety relays and control modules for proper integration of protective devices, along with signal towers and warning indicators that improve hazard communication. Hard guarding solutions range from standard machine guards to custom-fabricated enclosures designed for your specific equipment.

Product selection considers your machinery layout, operator workflow, maintenance accessibility requirements, and production speed demands. We help you understand the appropriate safety category for each application and recommend products that provide required protection levels without unnecessarily restricting legitimate equipment access or slowing production cycles.

Implementation support includes wiring diagrams for safety device integration, control logic review to ensure proper protective function, and coordination with your maintenance team to plan installation activities that minimize production interruption. Our engineers can provide on-site commissioning assistance to verify safety system performance and document compliance with applicable standards.

OSHA Compliance and Regulatory Guidance

OSHA compliance requirements vary based on your industry, equipment types, and specific operations, making it challenging to determine which standards apply to your facility and how to interpret regulatory language for practical application. Our engineers help you navigate these complexities by identifying applicable OSHA standards, explaining compliance requirements in practical terms, and recommending cost-effective approaches to satisfying regulatory obligations.

We stay current with OSHA regulatory changes and industry-specific guidelines that affect manufacturing safety requirements. This knowledge enables us to provide accurate guidance on compliance expectations and help you prioritize safety improvements based on regulatory risk and potential citation severity.

For situations requiring formal safety assessments or third-party certification, we can connect you with trusted partners who specialize in comprehensive compliance audits and regulatory documentation. These partnerships ensure you have access to qualified safety professionals when your situation demands certified evaluations or expert testimony.

Practical Safety Improvement Planning

Effective safety improvements require practical implementation plans that balance regulatory compliance with operational realities and budget constraints. Our engineers help you develop phased improvement strategies that address critical hazards promptly while scheduling longer-term upgrades in coordination with planned maintenance activities and capital equipment investments.

We provide realistic cost estimates for recommended improvements, including safety product pricing, installation labor requirements, and any necessary electrical or mechanical modifications. This financial information helps you secure appropriate funding and make informed decisions about which improvements to pursue immediately versus which can be scheduled for future implementation.

Our approach emphasizes solutions that enhance safety without unnecessarily complicating machine operation or creating maintenance difficulties. We understand that safety devices must work reliably in real production environments and recommend products proven to withstand the industrial conditions present in your facility.

Ongoing Safety Support and Product Sourcing

Safety improvement projects often require technical support beyond initial assessment and product selection. Our engineers remain available to answer questions during implementation, review installation plans for potential concerns, and assist with troubleshooting if safety devices don't perform as expected after installation.

We maintain extensive inventory of common safety products and can source specialized components quickly when your project timeline demands rapid delivery. Our relationships with major safety equipment manufacturers enable us to provide technical support for product selection, obtain application-specific documentation, and coordinate factory assistance when complex integration challenges arise.

As your manufacturing operations evolve, we can provide ongoing safety consulting to assess new equipment, evaluate production changes that may affect safety requirements, and recommend protective device upgrades that improve protection while incorporating advances in safety technology.

Request for Quote

Get detailed specifications and pricing for your safety audit or equipment safeguarding project. We provide comprehensive quotes that include assessment scope, recommended improvements, and implementation support.