Process Control Systems & Process System Engineering

When your manufacturing operation demands precise control over complex processes, Streamline Contract Manufacturing delivers process control systems that integrate seamlessly with your existing equipment while providing the monitoring and control capabilities modern production requires. Our team of experienced engineers combines deep technical expertise with practical manufacturing knowledge to design and fabricate custom process systems that keep your operations running efficiently and reliably.

As a specialized process systems contract manufacturer, we understand that every industrial application presents unique challenges. Our comprehensive approach to process system engineering addresses your specific requirements for pressure control, flow management, temperature regulation, and data acquisition while maintaining the safety standards and regulatory compliance your industry demands. We work closely with your engineering team to develop solutions that optimize performance while remaining within project budget and timeline constraints.

Custom Process System Design and Fabrication Capabilities

Our engineering team brings 90+ years of manufacturing experience to every process control project, designing systems that balance technical sophistication with operational simplicity. We evaluate your process requirements, environmental conditions, and integration needs before recommending solutions that address both immediate operational demands and long-term reliability objectives.

Process system engineering at Pearse Bertram encompasses complete project lifecycle support, from initial concept development through final commissioning and startup assistance. Our engineers work with you to understand critical process parameters, identify potential control challenges, and design systems that maintain consistent performance across varying operational conditions. This methodical approach ensures your process control systems deliver the precision and repeatability your manufacturing processes require.

We maintain extensive fabrication capabilities across multiple process control applications:

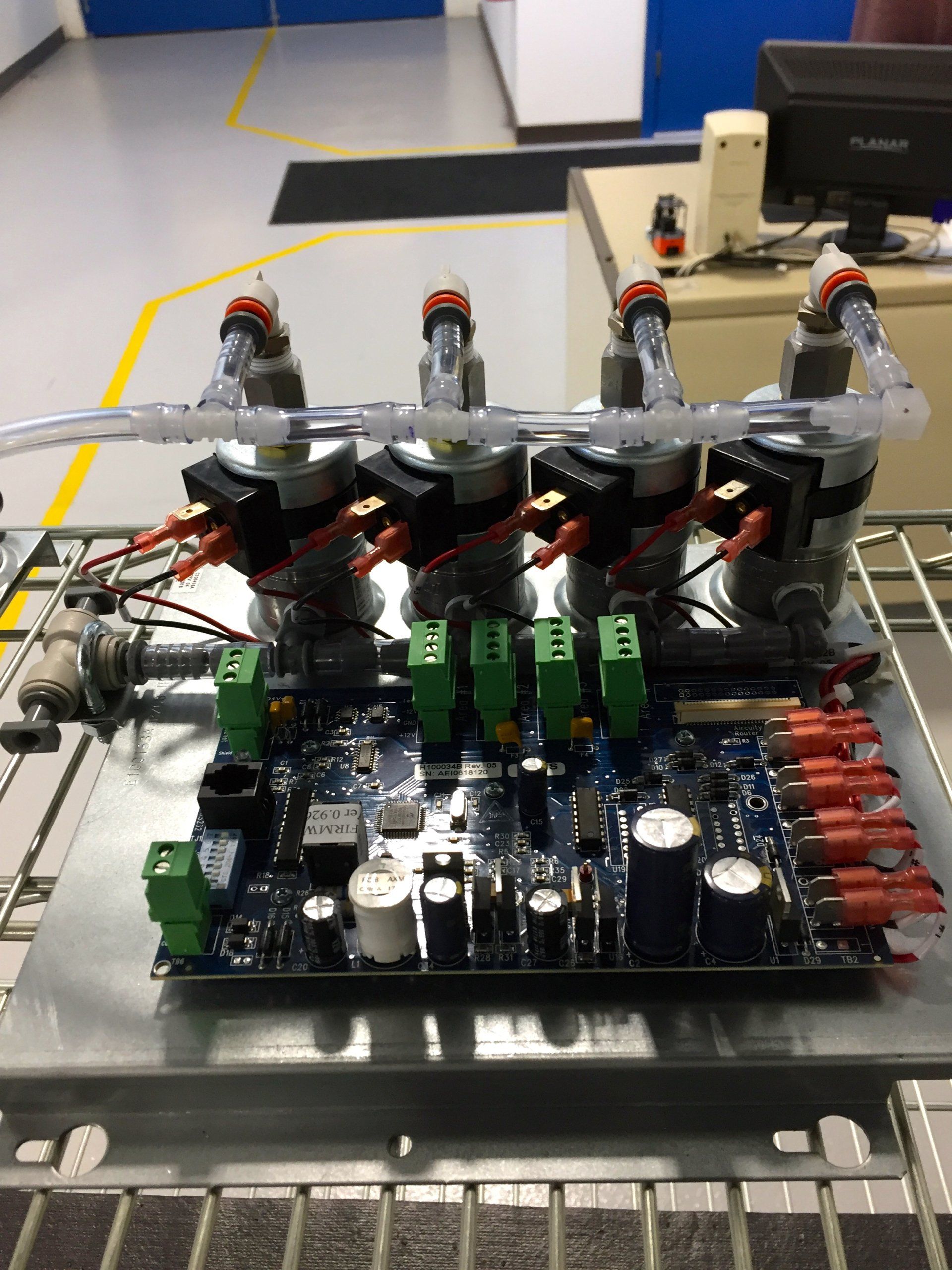

Gas boxes and panels

for semiconductor manufacturing, pharmaceutical processing, and specialty gas distribution applications

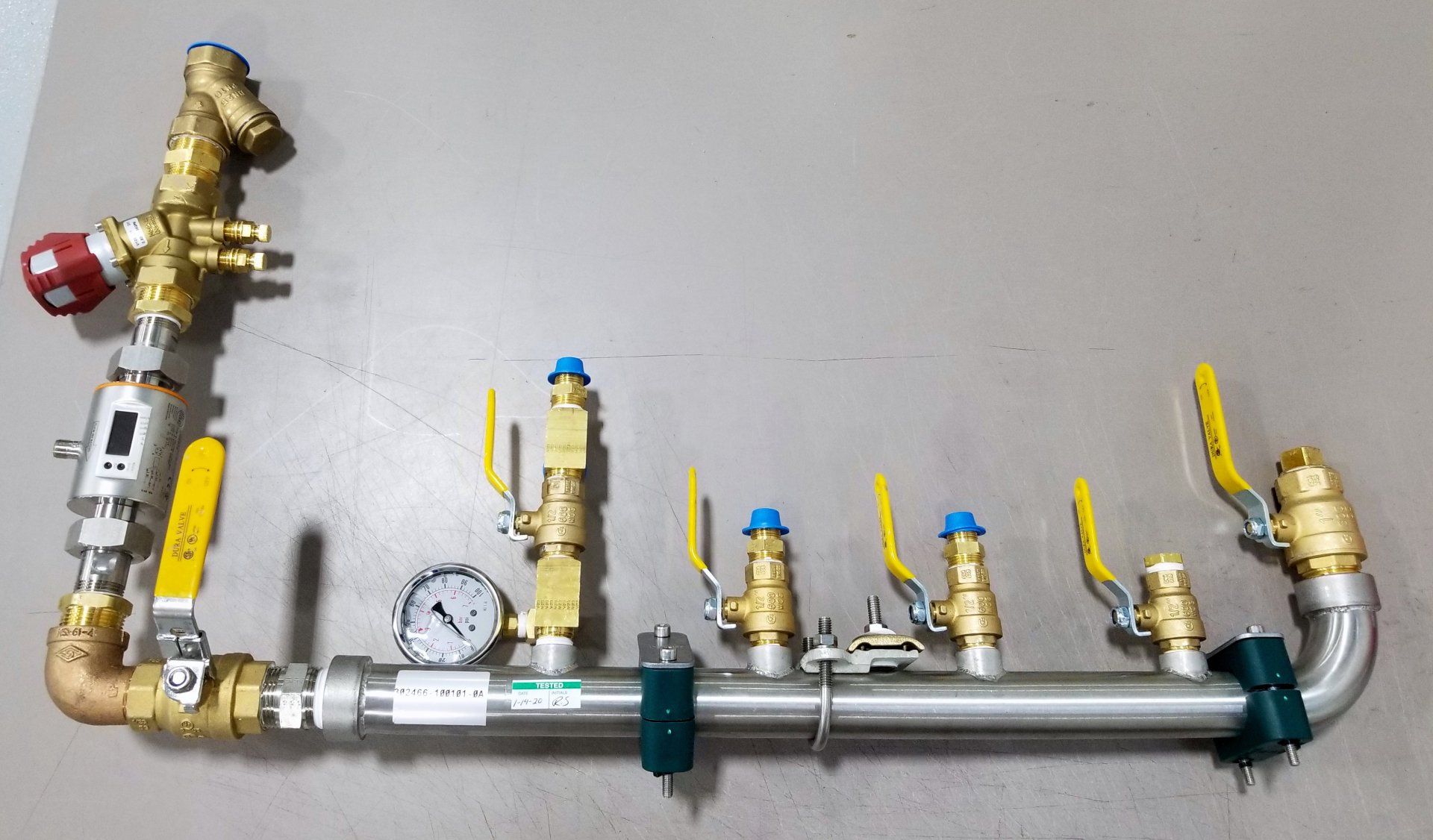

Custom fluid control manifolds and hose assemblies

designed for your specific pressure, flow, and compatibility requirements

Analytical instrumentation sub-assemblies

that integrate seamlessly with existing laboratory and production equipment

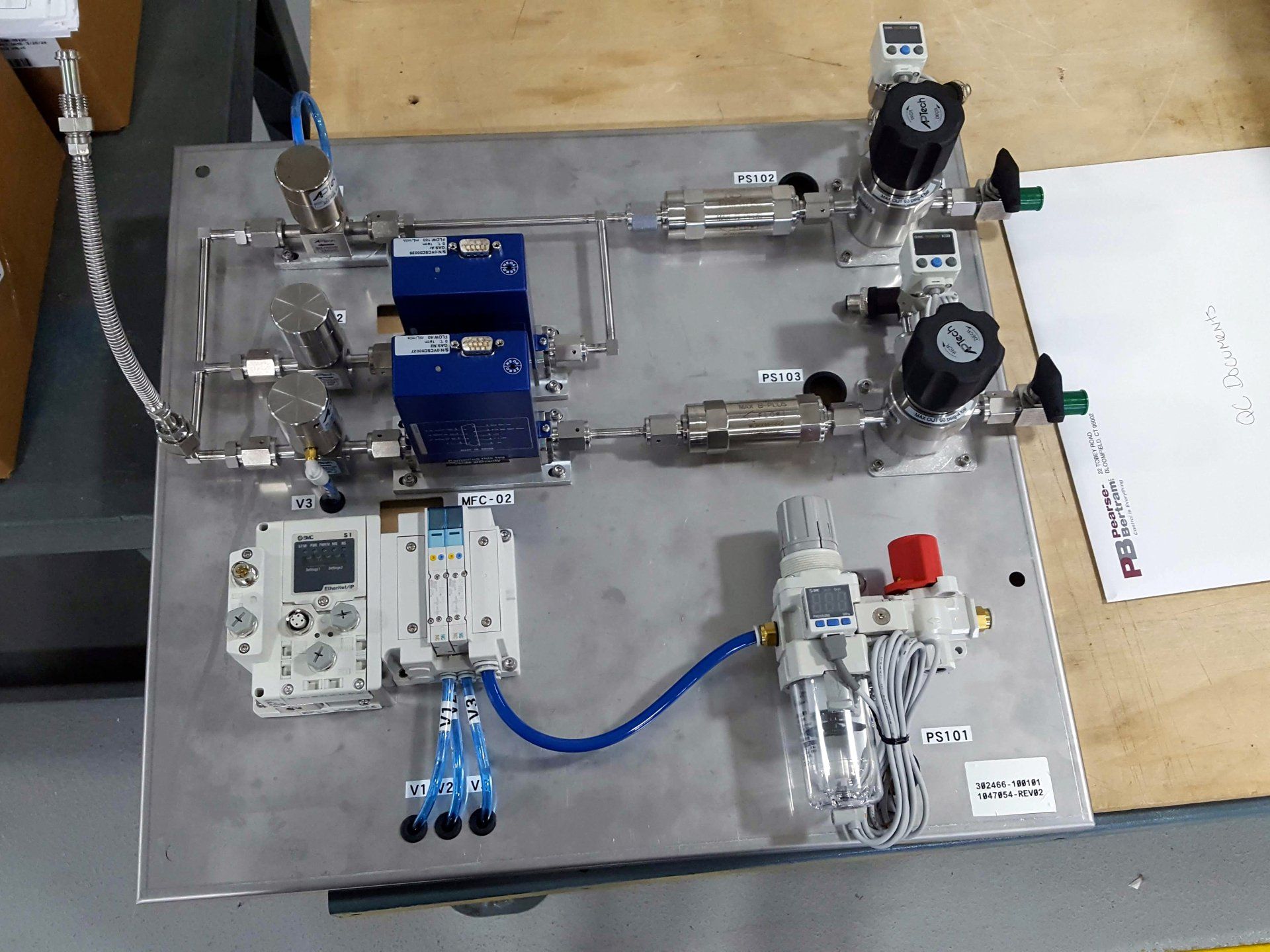

High purity liquid and gas delivery modules

in 304 or 316 stainless steel for cleanroom and controlled environment applications with an appropriate RA finish.

Custom pressure, vacuum, and air preparation systems

tailored to your process specifications

Caustic and washdown rated assemblies

for chemical processing, food and beverage, or water/wastewater applications requiring stainless steel or thermoplastic materials

Custom pump skids and cooling manifolds

to ensure coolant or fluidic distribution for your heat-dissapation (e.g. lasers)

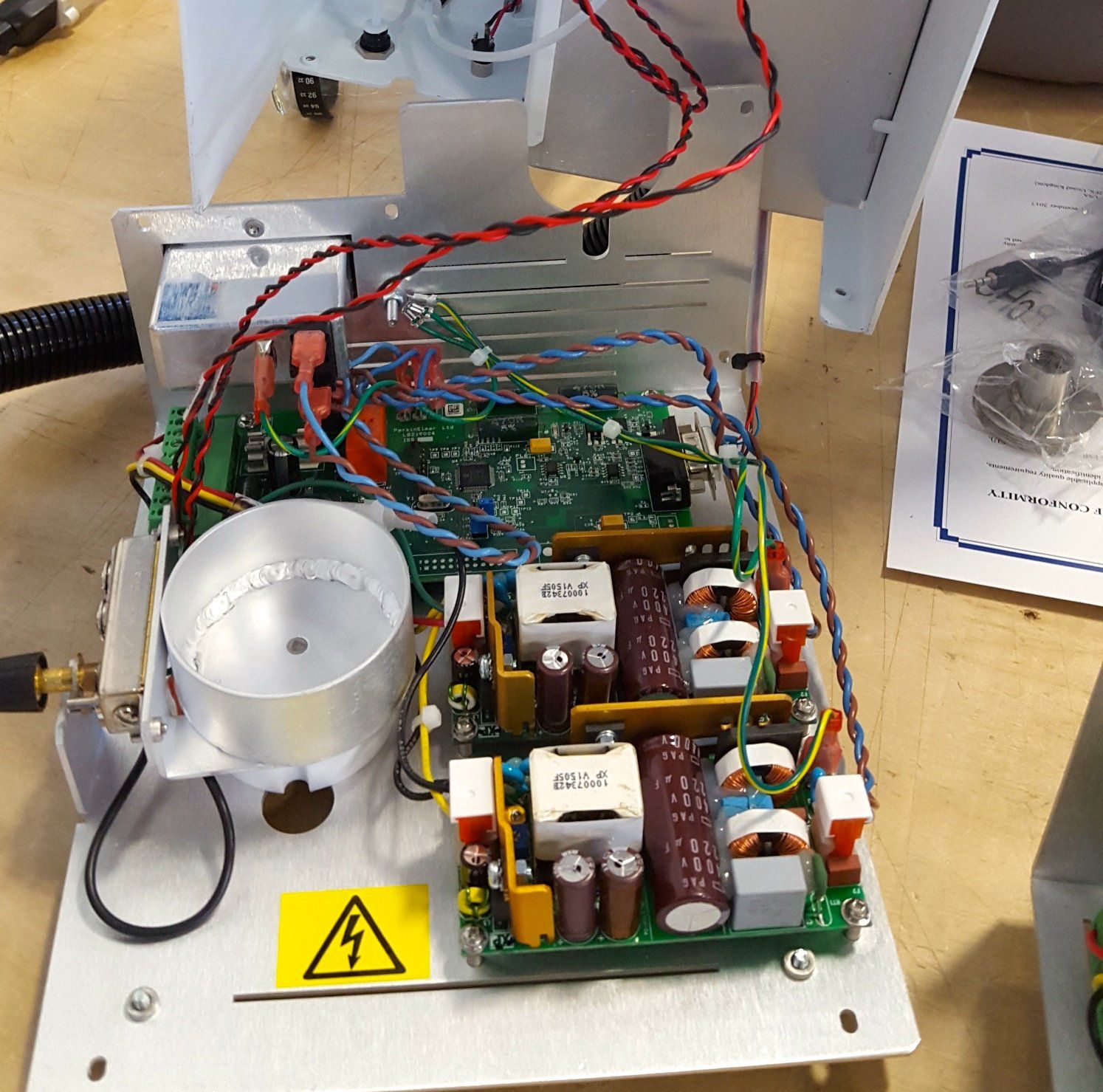

Custom tailored power monitoring systems

that notify when power loss or bad power quality occurs, or logs machine power usage for HSA and environmental green initiatives

Fully integrated test stands

for quality control, research and development, and production validation

Our ISO 9001:2015 certification demonstrates our commitment to consistent quality throughout the manufacturing process. IPC-A-620 certified technicians handle all cable, wire, and harness assemblies, ensuring reliable electrical connections that maintain signal integrity in demanding industrial environments. Comprehensive testing capabilities including vacuum decay tests, pressure decay testing, helium leak testing, and electrical verification ensure every system meets design specifications before leaving our facility.

Ask an Expert

Have questions about designing a process control system for your specific application? Our experienced engineers are ready to discuss your requirements and recommend solutions that optimize performance while meeting your operational objectives.

Closed-Loop Process Control and Monitoring Systems

Modern process control systems require continuous monitoring and real-time adjustment to maintain optimal operating conditions. Our closed-loop process systems offer comprehensive monitoring of critical parameters including pressure, flow, viscosity, pH, humidity, and temperature, gathering the data you need for ongoing process optimization and troubleshooting. These integrated control solutions provide the visibility and control capabilities necessary for maintaining consistent product quality while reducing waste and improving operational efficiency.

Process monitoring systems we design and fabricate incorporate industry-standard sensors, transducers, and control devices from leading manufacturers. We integrate these components with programmable logic controllers and human-machine interfaces that provide operators with intuitive control over process parameters. Data logging SQL and trending capabilities enable your team to identify process variations before they impact product quality or equipment performance.

Our experience spans multiple process control applications including panels with integrated PC boards and process control valves that manage complex sequences and maintain precise control over critical parameters. Pump control systems we engineer regulate flow rates, maintain system pressure, and protect equipment from operating conditions that could cause damage or premature wear. Whether your application involves hydraulic controls for heavy machinery, gas controls for chemical processing, water management for pharmaceutical production, or pneumatic controls for automation systems, our engineers design solutions that address your specific operational requirements.

Industry-Specific Process System Solutions

Process control requirements vary significantly across industries, and our engineers understand the unique challenges different manufacturing environments present. Pharmaceutical and biotechnology facilities require process systems that support validation requirements, maintain cleanroom compatibility, and provide complete documentation for regulatory compliance. Food and beverage processing operations demand hygienic design principles, easy cleaning procedures, and materials that withstand frequent sanitization cycles.

Chemical processing applications often involve corrosive or hazardous materials that require specialized materials selection, containment strategies, and safety interlocks. Semiconductor manufacturing demands ultra-high purity gas and liquid delivery systems with minimal contamination risk and precise flow control. Our engineering team evaluates these industry-specific requirements during the design phase and incorporates appropriate features and safeguards into every process control system we fabricate.

Environmental monitoring and control capabilities can be integrated into process systems when applications require precise temperature management, humidity control, or atmospheric composition regulation. Our engineers design thermal management solutions, implement redundant control strategies for critical processes, and incorporate alarm and notification systems that alert operators to conditions requiring attention. This comprehensive approach ensures your process control systems maintain optimal operating conditions while protecting equipment and personnel from potentially hazardous situations.

Advanced Testing and Quality Assurance

Quality assurance measures throughout our fabrication process ensure consistent results and reliable system performance. Incoming component inspection verifies that materials and devices meet specified requirements before entering production. In-process quality checks during assembly and integration catch potential issues early, reducing rework and maintaining project schedules. Final testing protocols validate system performance against design specifications and customer requirements.

Our facility maintains specialized testing capabilities that support rigorous quality verification. Helium leak testing identifies even microscopic leaks in high-purity gas systems, ensuring containment integrity for critical applications. Pressure testing verifies system strength and confirms proper operation under rated conditions. Vacuum testing evaluates system performance in applications requiring controlled atmospheric conditions. These comprehensive testing protocols provide confidence that systems will perform as designed when installed in your facility.

Documentation packages accompanying every process control system include detailed assembly drawings, component specifications, test certificates, and operation manuals. This thorough documentation supports installation activities, facilitates operator training, and provides maintenance personnel with information necessary for long-term system support. We also provide electrical schematics, pneumatic diagrams, and control logic documentation that enable your team to understand system operation and perform troubleshooting when necessary.

Project Management and Installation Support

Process control system projects require careful coordination between design, fabrication, and installation activities to meet project schedules and operational objectives. Our project management approach focuses on clear communication, realistic scheduling, and proactive problem-solving that keeps projects moving forward smoothly. We provide regular progress updates, coordinate delivery timing with your installation schedule, and remain flexible enough to accommodate changing requirements that emerge during project execution.

Installation support services help ensure successful system commissioning and startup. Our engineers can provide on-site supervision during installation, verify proper connections and system integration, and assist with initial startup procedures. We work with your operations team to develop startup sequences that safely bring systems online while verifying proper operation of all components and control functions. Operator training ensures your personnel understand system operation, recognize normal operating conditions, and know how to respond to alarms or unusual conditions.

Long-term support capabilities extend beyond initial installation to include preventive maintenance planning, spare parts identification, and system modification services as your process requirements evolve. Our engineers remain available to answer technical questions, provide troubleshooting assistance, and recommend system improvements based on operational experience. This ongoing partnership approach reflects our commitment to supporting your success throughout your equipment's operational life.

FAQs

What types of process control systems do you design and fabricate?

We design and fabricate a variety of custom process control systems including gas boxes and gas panels for semiconductor and pharmaceutical applications, custom fluid control manifolds and hose assemblies, analytical instrumentation sub-assemblies, high purity liquid and gas delivery modules, custom pressure/vacuum/air preparation systems, caustic and washdown rated assemblies, custom pump skids and cooling manifolds, power monitoring systems, and fully integrated test stands.

What are gas boxes and panels, and what industries use them?

Gas boxes and panels are control systems that safely control and distribute specialty gases (e.g. nitrogen, helium, argon, etc.) for semiconductor manufacturing, pharmaceutical processing, medical uses, laboratory research, and specialty gas distribution applications. These systems incorporate precise flow control, pressure regulation, safety interlocks, and monitoring to ensure safe handling of potentially hazardous gases in cleanroom and controlled environment applications.

Can you design high-purity liquid and gas delivery modules?

Yes, we fabricate high purity liquid and gas delivery modules in 304 or 316 stainless steel for cleanroom and controlled environment applications with appropriate RA finish. These modules are designed for pharmaceutical, semiconductor, and laboratory applications requiring contamination-free gas/fluid delivery with precise flow control and monitoring.

What are caustic and washdown rated assemblies?

Caustic and washdown rated assemblies are designed for chemical processing, food and beverage, or water/wastewater applications using stainless steel or thermoplastic materials that withstand aggressive chemicals and frequent cleaning. These assemblies feature hygienic design principles, corrosion-resistant construction, and easy-to-clean surfaces that meet sanitation requirements for regulated industries.

What applications require custom pump skids and cooling manifolds?

We design custom pump skids and cooling manifolds to ensure coolant or fluidic distribution for heat dissipation applications such as laser cooling, process cooling, and thermal management systems. These skid-mounted systems integrate pumps, heat exchangers, filtration, control valves, and instrumentation in compact, pre-tested packages ready for installation.

What are custom tailored power monitoring systems?

Our custom power monitoring systems notify operators when power loss or bad power quality occurs, and log machine power usage for HSA (Health and Safety Administration) and environmental green initiatives. These systems help you track energy consumption, identify power quality issues before they cause equipment problems, and document energy usage for sustainability reporting.

What are fully integrated test stands and what do they include?

Fully integrated test stands are complete testing systems for quality control, research and development, and production validation. We design and build test stands incorporating pressure testing, flow measurement, electrical verification, data acquisition, and automated pass/fail criteria. These systems include custom fixtures, instrumentation, control panels, and software for comprehensive product validation and documentation.

What testing capabilities do you have for process systems?

Our facility maintains specialized testing including helium leak testing for high-purity gas systems, pressure decay testing to verify system integrity, vacuum decay testing for controlled atmosphere applications, and comprehensive electrical verification. We also provide hydrostatic testing, functional performance validation, and system commissioning before shipment.

Do you provide closed-loop process control and monitoring systems?

Yes, we design closed-loop process control systems that continuously monitor and adjust critical parameters including pressure, flow, viscosity, pH, humidity, and temperature. These systems integrate industry-standard sensors with programmable logic controllers and HMIs, providing data logging, trending capabilities, and alarm notification to maintain optimal operating conditions.

What documentation do you provide with process control systems?

Every process control system includes detailed assembly drawings, component specifications, test certificates, operation manuals, electrical schematics, pneumatic diagrams, and control logic documentation. For FDA-regulated industries, we provide complete validation documentation packages including IQ/OQ protocols and material certifications.

Do you provide installation support and operator training?

Yes, we offer on-site installation supervision, system commissioning, startup assistance, and operator training. Our engineers verify proper connections and integration, develop safe startup sequences, and ensure your team understands system operation, normal conditions, and proper response to alarms.

Do you have clean room capabilities?

Pearse Bertram does have clean room assembly capabilities depending on the class of clean room and size of the assembly. We are familiar with making special modifications to our assembly area for clean room requirements.

Request for Quote

Get detailed specifications and pricing for your custom process system project. We provide comprehensive quotes that include technical details, timeline, and complete project scope.