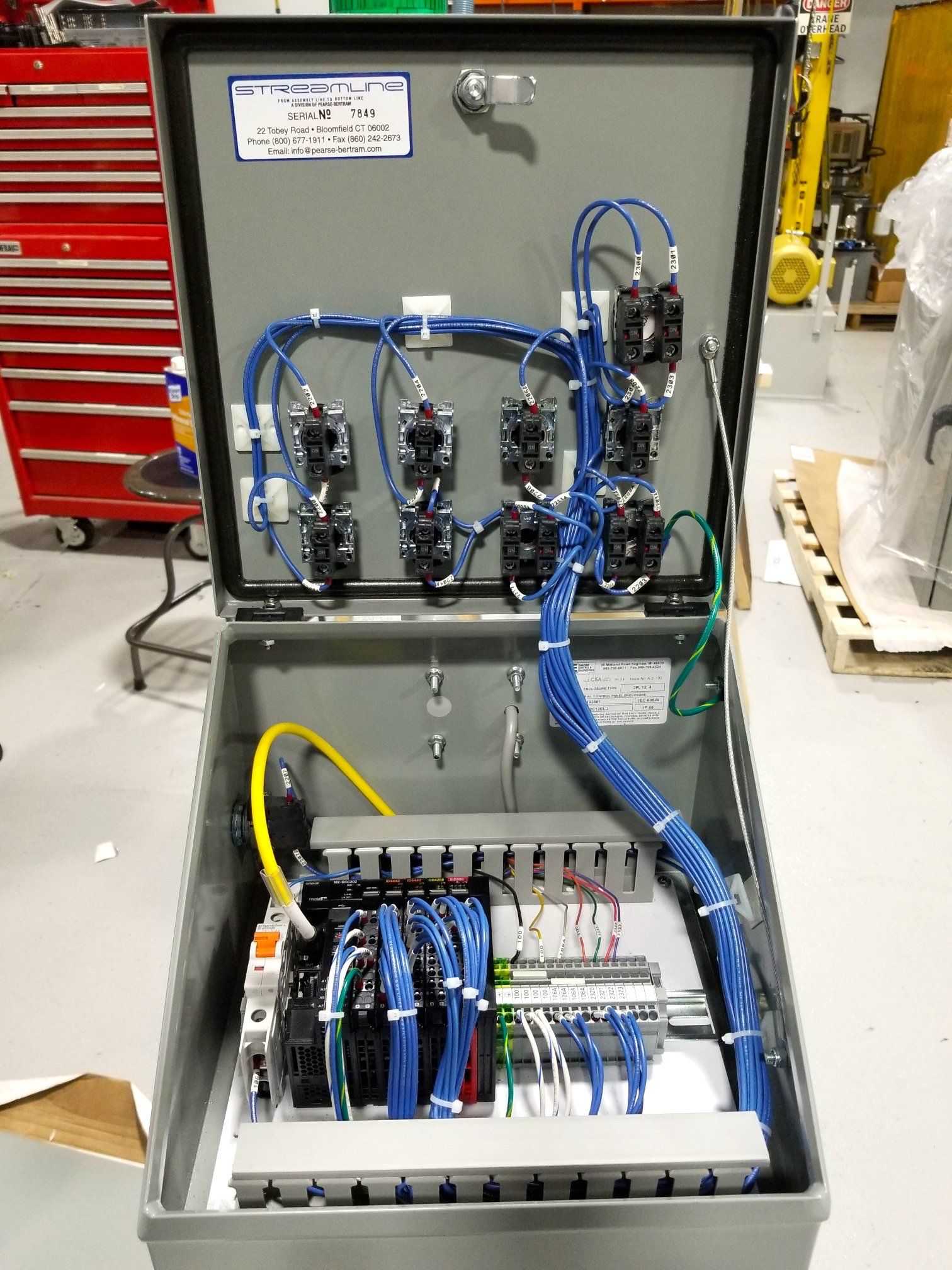

Electrical Control Panel Fabrication Services

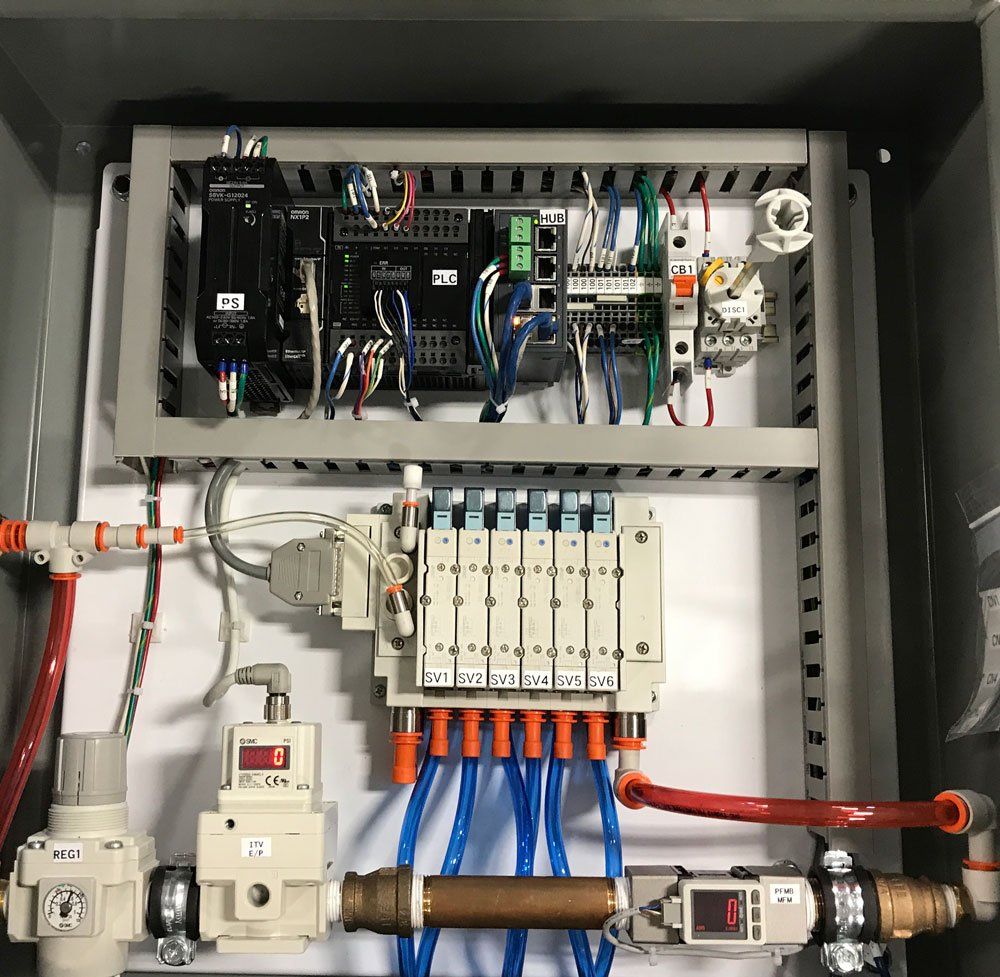

When you need electrical control panel fabrication that gets the job done right, our team at Streamline Contract Manufacturing brings 90+ years of New England manufacturing experience to your project. We're UL 508A certified engineers who design and build custom control panels from 12VDC to 600VAC systems, handling everything from compact motor controls to complex multi-system integration panels.

We understand that your control panel needs to pass inspection on the first pass and perform reliably for years. Our

control panel design process starts by understanding your electrical loads, environmental conditions, and communication requirements, then we build panels that meet

NEC Article 409 requirements while maintaining code compliance throughout all US states and Canada including Massachusetts, Connecticut, New Hampshire, Vermont, New York, Rhode Island, Maine, and New Jersey. With a product return rate under 0.5%, we're confident our panels will work as specified when they arrive at your facility.

Ask an Expert

Our engineers can answer technical questions about panel specifications, component selection, and compliance requirements for your application. Let's discuss your specific needs.

Industry-Specific Applications

Design and Fabrication Process

Documentation Package

We provide comprehensive documentation because we know your maintenance team will need it:

Engineering Drawings

- Single-line electrical diagrams showing power distribution

- Panel layout drawings with component locations and dimensions

- Detailed wiring diagrams with wire numbers and terminal designations

- PLC I/O assignments and network configuration diagrams

- HMI screen layouts and navigation structure

Compliance Documentation

- UL 508A short form and panel label

- Bill of materials with manufacturer part numbers

- Component specification sheets and certifications

- Test certificates for electrical performance

- As-built drawings reflecting any field modifications

Operational Support

- Operation and maintenance manuals

- Troubleshooting guides with common issues and solutions

- Recommended spare parts list with supplier information

- PLC program documentation with descriptions of all routines

- HMI screen prints with operational instructions

Project Delivery and Support

Standard lead time for custom control panel design and fabrication is 4-6 weeks for panels under 50 I/O points, 6-8 weeks for 50-200 I/O points, and 8-12 weeks for systems exceeding 200 points. The design phase typically requires 1-2 weeks depending on complexity. We'll coordinate delivery timing with your project schedule and keep you updated throughout fabrication.

Need help with installation? We provide on-site supervision when specified, including startup assistance, loop checking, and operator training. Our engineers remain available for technical support during commissioning and throughout the operational life of your control system. Because we're based in New England and focused on regional manufacturing, you can reach us when you need us.

Service and Modifications

We support the panels we build. If you need troubleshooting assistance, component replacement, or system upgrades, our engineers can help. We can even reverse-engineer undocumented panels, create as-built drawings, and implement modifications that maintain UL compliance.

We stock common replacement parts for faster response when unplanned repairs are needed. After 90+ years in business, we've learned that long-term customer relationships matter more than one-time transactions, so we'll be here to support your panel for its entire service life.

FAQs

What is UL 508A certification and why is it important?

As a contract manufacturer, Pearse Bertram can build an industrial control panel and apply a “UL sticker” to that assembly. UL 508A is a set of formally-recognized safety standards for manufacturers creating industrial control panels to be installed in the US or Canada. Our UL 508A certification ensures your control panel meets National Electrical Code Article 409 and will pass inspection by jurisdictions requiring this certification reducing project delays and ensuring worker safety (e.g. short circuit trip capacity).

Is UL 508A certification legally required?

While not always legally mandated, UL 508A compliance is frequently required by industrial equipment purchasers, state/local electrical inspectors, insurance providers, and facility safety managers. Many industries will not approve non-certified panels for installation.

How do I choose the right NEMA enclosure rating?

NEMA ratings depend on your environmental conditions. NEMA 1 is suitable for indoor general purpose applications. NEMA 4X provides corrosion-resistant protection for outdoor or washdown environments. NEMA 12 offers dust-tight, drip-tight protection for industrial settings. Our engineers assess your specific environment during consultation.

What information do you need to quote a control panel project?

We can help you regardless of how little or how much information you have. If you are interested in contract manufacturing, we generally ask for any and all information you do have including electrical load requirements (voltage, current, power consumption), environmental conditions, physical space constraints, code compliance requirements, I/O count (digital/analog inputs and outputs), communication protocol requirements, and HMI needs. Our engineers will review your specifications and recommend optimal solutions.

Can you design panels for hazardous locations?

Yes, our engineers design Class I Division 1 and 2 rated panels for hazardous locations, including explosion-proof and intrinsically safe designs. We understand ATEX requirements for European markets and can design panels for various hazardous atmosphere classifications.

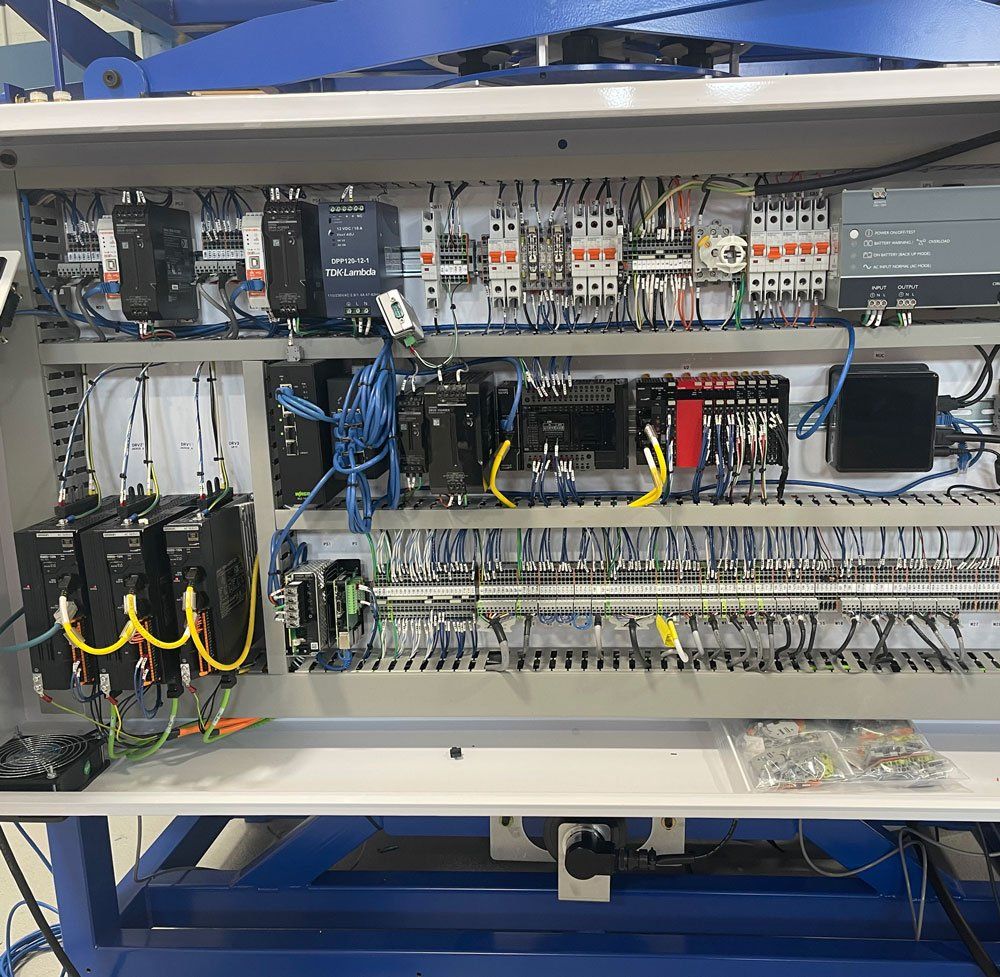

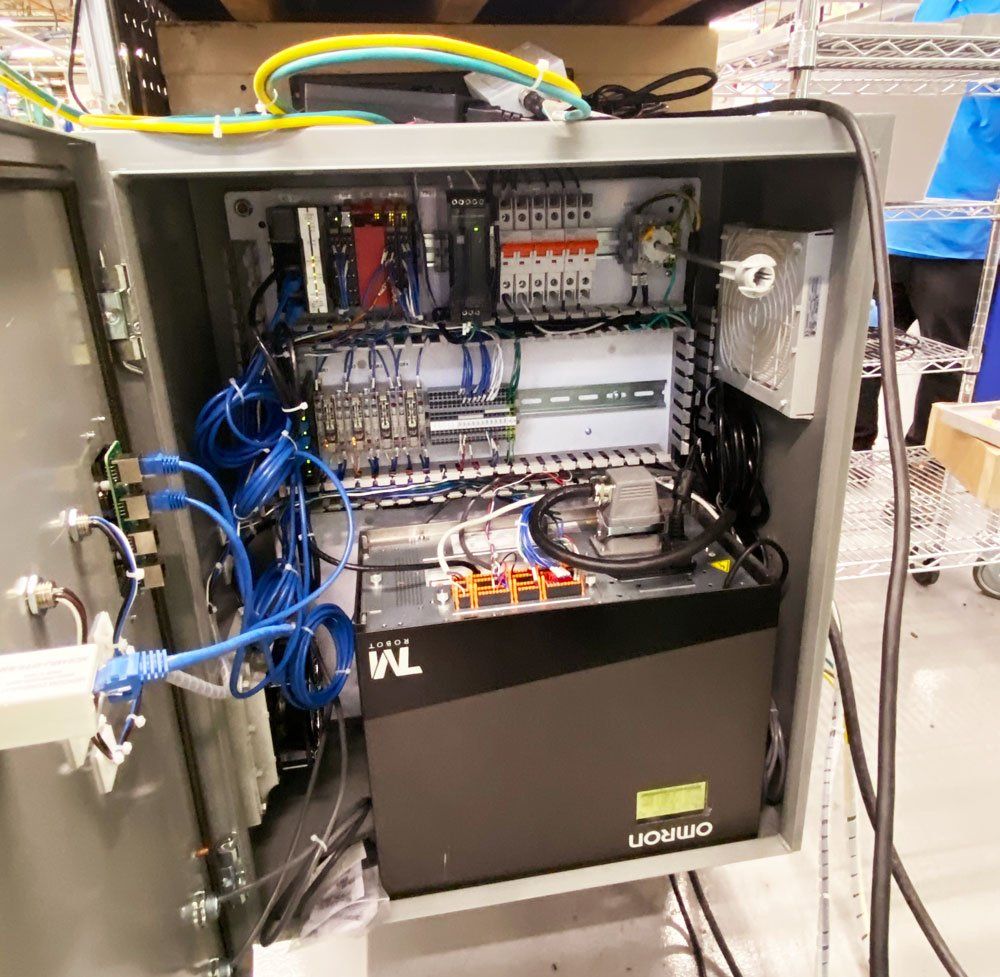

What PLC platforms do you work with?

We have extensive experience with Omron (Sysmac Studio and CX-One), Wago (CODESYS), and Unitronics. We select the optimal platform based on your application requirements, existing infrastructure, and maintenance capabilities.

Do you provide complete documentation packages?

Yes, every control panel includes AutoCAD electrical drawings, panel layout documents, complete wiring diagrams, bill of materials, UL 508A compliance documentation, test certificates, and operation/maintenance manuals in both hard copy and electronic formats.

What is your typical lead time for control panels?

Standard panels under 50 I/O points typically require 4-6 weeks from approved design. Complex panels (50-200 I/O) need 6-8 weeks. Large systems (200+ I/O) generally take 8-12 weeks. Rush orders can often be accommodated with expedited scheduling. Once a stocking program is established, lead time can be cut down to as quick as one day. We provide accurate timelines during the quoting process, and rushes can be made.

Can you modify or upgrade existing control panels?

On a case by case basis. We are generally not equipped to modify existing panels at an end-user. However, we do have partners that we can refer you to for that kind of work. However, we are happy to take existing designs and upgrade panel designs meant for repeat production.

What testing do you perform before shipment?

We conduct comprehensive testing including continuity checks, insulation resistance testing, functional verification of all circuits, communication protocol validation, and load testing where applicable. All test results are documented and provided with your panel.

Request for Quote

Provide your electrical load requirements, environmental conditions, and I/O count for a detailed fabrication quote with specifications and timeline.