Robotics

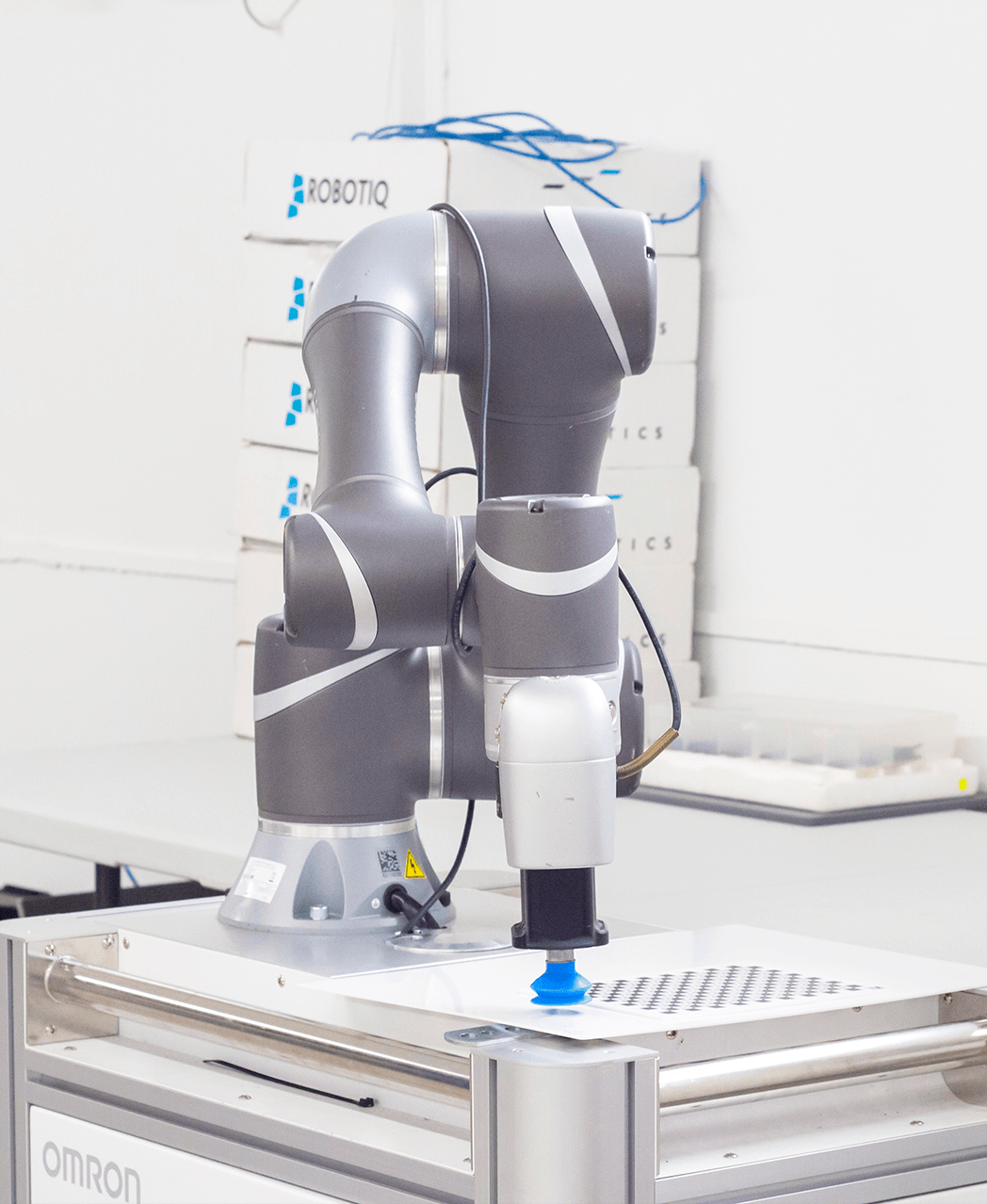

When your manufacturing operation requires precision, repeatability, and operational efficiency that human labor alone cannot consistently deliver, Pearse Bertram's robotic system integration services provide engineered automation solutions that extend your team's capabilities. Our experienced engineers combine 90+ years of industrial automation expertise with advanced robotics technology from Omron to design and implement custom robotics solutions that address your specific production challenges while maintaining the flexibility your operation demands. Through the association and development of Techman, and Adept, Omron offers a full suite of industrial robots including SCARA, AMR (Autonomous Mobile Robots), Collaborative 6-axis, Delta/Spyder, and standard Industrial Robots.

As specialists in industrial robotics integration for New England manufacturing facilities, we understand that successful automation projects require more than just installing equipment. Our comprehensive approach to custom robotics implementation encompasses application analysis, system design, integration with existing processes, and ongoing support to ensure your robotic systems deliver the productivity gains and quality improvements your business needs.

A Powerful Extension of Your Team

Industrial robots represent a strategic investment in your operation's future, serving as reliable partners that work alongside your skilled workforce to handle repetitive tasks with unwavering consistency. Our robotic solutions bring precision and reliability to applications including assembly operations, quality inspection, product packing, drilling operations, machine tending, and other factory automation requirements that demand consistent performance across every production cycle.

With a maximum reach of four feet (1,300mm), our range of robotic solutions accommodates diverse manufacturing environments and application requirements. Whether you need to automate a single process or integrate multiple robotic cells across your facility, our engineers design systems that fit seamlessly into your existing production flow while providing the flexibility to adapt as your operational needs evolve.

The value of industrial robotics integration extends beyond simple task automation. Robots excel at maintaining consistent quality standards, operating in challenging environments, and performing with precision that human operators find difficult to sustain hour after hour. By deploying robotics strategically within your operation, you free your skilled workforce to focus on higher-value activities requiring human judgment, problem-solving, and adaptability while robots handle the repetitive precision work they perform exceptionally well.

Ask an Expert

Have questions about implementing robotic automation in your manufacturing operation? Our experienced engineers are ready to discuss your specific application requirements and recommend the optimal industrial robotics integration solution for your facility.

Meet Production Demands with Reliable Precision

An industrial robot delivers value only when it operates reliably, performing assigned tasks with consistent precision across thousands of production cycles. Our precision-driven robotics are engineered for repeatability of ±0.05 millimeters, ensuring that every part, every assembly, and every inspection meets your exacting quality standards regardless of production volume or shift duration.

This level of precision enables applications that demand consistent dimensional accuracy, proper component alignment, and repeatable process execution. Whether you're assembling small electronic components, inspecting machined parts, or handling delicate products, our robotic solutions maintain the accuracy your quality standards require while operating at speeds that meet your production throughput demands.

Best-in-class safety features protect your workforce while enabling productive collaboration between human operators and robotic systems. Our collaborative robotic offerings incorporate superior body region safety settings that detect human presence and stop instantaneously when sensing nearby personnel. This advanced safety technology allows robots and people to work in close proximity without requiring extensive safety guarding, reducing floor space requirements while maintaining the highest protection standards for warehouse and factory staff.

Safety considerations extend throughout our robotic system integration process. We design installations that comply with relevant safety standards, implement appropriate safeguarding measures, and provide comprehensive operator training that emphasizes safe interaction with robotic equipment. This thorough approach to safety ensures your team can work confidently alongside robotic systems while maintaining full regulatory compliance.

Versatile Solutions for Multiple Applications

One robotic system can serve multiple machines and processes, maximizing your automation investment while maintaining operational flexibility. Modern industrial robots for manufacturing incorporate sophisticated control capabilities that enable them to adapt between different tasks, handle various product configurations, and integrate with diverse equipment types across your facility.

Features including graphical programming interfaces simplify system configuration and modification, allowing your team to adjust robotic operations as production requirements change. Barcode reading capabilities enable robots to identify parts, track production data, and make real-time decisions based on product information. Pattern matching technology allows robots to locate parts in variable positions, accommodating natural process variations while maintaining consistent handling precision.

Vision systems expand robotic capabilities beyond simple position-based movements. Integrated cameras and image processing enable robots to inspect product quality, verify assembly completeness, and adapt to variable part presentations. This visual intelligence transforms robots from simple position repeaters into flexible automation tools that respond intelligently to real-world production conditions.

Communication protocols allow robotic systems to integrate seamlessly with your existing automation infrastructure. Our engineers design solutions that exchange data with programmable logic controllers, human-machine interfaces, and manufacturing execution systems, ensuring your robotic cells operate as coordinated components within your overall production system rather than isolated automation islands.

Custom Robotics Implementation Process

Successful industrial robotics integration begins with thorough application analysis and process understanding. Our engineers visit your facility to observe current operations, identify automation opportunities, and discuss your production objectives. This hands-on assessment reveals the technical requirements, physical constraints, and operational considerations that inform optimal system design.

We evaluate cycle time requirements, product handling characteristics, integration points with existing equipment, and operator interaction needs to develop robotic solutions that address your specific challenges. This detailed analysis phase prevents costly design mistakes and ensures the final system meets your operational requirements while remaining within project budget constraints.

System design incorporates proven robotic platforms selected for your application requirements. We specify appropriate payload capacity, reach dimensions, speed capabilities, and accuracy specifications based on your process demands. End-of-arm tooling receives careful attention, as the gripper or tool interface represents the critical connection between robot and product that directly impacts system performance.

Simulation and offline programming allow us to validate system design before fabrication begins. Using digital twins of your production environment, we verify robot reach, identify potential collisions, optimize motion paths, and refine cycle times. This virtual commissioning approach reduces onsite installation time while increasing confidence that the physical system will perform as intended.

Integration with Existing Manufacturing Systems

Robotic automation projects succeed when new systems integrate smoothly with established processes and equipment. Our engineers design interfaces that connect robotic cells with conveyor systems, assembly fixtures, inspection equipment, and material handling infrastructure already present in your facility. This integration approach preserves your existing capital investments while enhancing overall system capabilities.

Control system integration receives particular attention during system design. We implement communication protocols that enable robotic systems to coordinate with existing programmable logic controllers, exchange production data with manufacturing execution systems, and respond to signals from upstream and downstream processes. This comprehensive integration ensures your robotic cells operate as synchronized components within your overall production flow.

Operator interfaces balance technical capability with user-friendly operation. We design human-machine interface screens that provide operators with clear production status, simple program selection, and straightforward troubleshooting guidance. This attention to operator experience encourages acceptance of robotic systems while reducing training time and minimizing operational errors.

Quality assurance measures validate system performance throughout the integration process. We conduct thorough testing of robotic movements, verify safety system operation, confirm proper communication with ancillary equipment, and validate that the complete system meets specified cycle times and quality standards. This systematic approach to quality verification ensures your robotic system performs reliably from day one of production operation.

Applications Across Manufacturing Industries

Robotic system integration serves diverse manufacturing sectors, each with unique requirements and operational challenges. Assembly operations benefit from robotic precision and consistency, whether joining small electronic components or assembling large mechanical assemblies. Robots handle parts with repeatable orientation, apply precise forces during insertion operations, and maintain consistent quality across every assembly cycle.

Machine tending applications leverage robotic reliability to maximize production equipment utilization. Robots load raw materials, remove finished parts, and transfer components between manufacturing operations without fatigue or attention lapses. This consistent machine feeding enables lights-out manufacturing operations while freeing operators for higher-value activities requiring human judgment.

Inspection and testing operations gain speed and objectivity through robotic automation. Vision-equipped robots examine parts for dimensional accuracy, surface defects, and assembly completeness with consistent criteria application. Automated inspection eliminates subjective judgment variations while documenting every measurement for quality record requirements.

Packaging operations utilize robotic flexibility to handle diverse product configurations and package styles. Robots adapt to different case sizes, arrange products in optimal orientations, and adjust operations for promotional packaging variations. This flexibility maintains high packaging line efficiency even as product mix changes throughout production shifts.

Training and Operational Support

Comprehensive operator training ensures your team can effectively utilize robotic systems while maintaining safe operation. We provide hands-on instruction covering system operation, basic troubleshooting, and routine maintenance procedures. Training programs are tailored to your team's technical background, emphasizing practical skills that support confident system operation.

Documentation packages include detailed operational procedures, maintenance schedules, and troubleshooting guides. We provide electrical schematics, pneumatic diagrams, and robot program documentation that support your maintenance team's ability to service equipment effectively. This thorough documentation approach reduces dependence on outside service providers while ensuring proper system care.

Ongoing technical support remains available after system commissioning. Our engineers provide remote troubleshooting assistance, application guidance, and advice on system optimization as your production requirements evolve. This long-term partnership approach reflects our commitment to your continued success rather than treating system installation as the end of our engagement.

Preventive maintenance planning helps maximize robotic system reliability and operational life. We recommend maintenance schedules based on manufacturer guidelines and application demands, identifying critical service tasks that prevent unexpected downtime. Regular maintenance preserves system accuracy, extends component life, and maintains the performance your production schedule depends upon.

FAQs

What robot brands do you work with?

We represent the Omron robotics lineup. We select robots based on your application requirements including payload, reach, speed, and precision needs.

What types of robots does Omron offer?

Omron offers industrial robots including SCARA, Mobile, Collaborative, and Delta. Their robot lineup is limited to payloads of 25kg and reaches of 1300mm, so they are meant for smaller applications.

How do I know if robotics is right for my application?

Robotics make sense for repetitive tasks, hazardous operations, precision requirements beyond manual capabilities, or when labor availability limits production. Our engineers assess your application, cycle time requirements, and ROI expectations to recommend appropriate solutions.

What is the typical ROI for robotic automation?

ROI varies by application but many clients see payback within 1-3 years through increased throughput, reduced labor costs, improved quality, and decreased scrap. We provide detailed ROI analysis during the proposal phase including productivity gains and total cost of ownership.

Do you provide robot programming and teaching services?

Yes, our certified robot programmers develop optimized programs for pick-and-place, palletizing, machine tending, welding, and assembly applications. We also offer operator training so your team can make routine program adjustments.

How do you ensure robot safety compliance?

We design robot cells following ANSI/RIA R15.06 standards including appropriate safeguarding (light curtains, safety scanners, interlocks), risk assessments, and safety PLC integration. Every installation includes proper documentation and operator training on safety procedures.

Can you integrate robots with our existing equipment?

Yes, we specialize in integrating robots with CNCs, injection molding machines, press brakes, and other production equipment. We handle all aspects including mechanical interfaces, electrical integration, and coordinated control logic.

What is the difference between industrial robots and collaborative robots?

Industrial robots are typically faster and handle heavier payloads but require safety caging. Collaborative robots (cobots) are designed to work safely alongside people without guarding but have lower payloads and speeds. We help determine which approach suits your application.

How long does a typical robot integration project take?

Project timelines vary based on complexity. Simple pick-and-place applications may take 12-16 weeks, while complex systems with custom end-of-arm tooling and vision integration can require 6-9 months. We provide detailed project schedules during planning.

Do you provide robot maintenance after installation?

In general, no. But, we offer preventive maintenance information and spare parts support.

Request for Quote

Get detailed specifications and pricing for your custom robotics implementation project. We provide comprehensive proposals that include technical details, timeline, integration requirements, and complete project scope.