Expert Product Selection Support Services for Industrial Automation

When your product engineers encounter technical questions or have questions about optimizing their BOM for production, having access to experienced engineering expertise that has decades of experience with over 100 OEM product lines makes the difference. Pearse Bertram's application support services provide the technical guidance and hands-on assistance that New England manufacturers rely on to find and recommend the absolute best product for their application from over 100 different industry-recognized brands.

Our team of experienced engineers brings 70+ years of combined manufacturing expertise to every application support engagement. We understand that today's industrial automation systems integrate multiple technologies across pneumatics, hydraulics, electrical control, and process automation. This complexity demands engineering partners who can evaluate problems holistically and recommend solutions that address root causes rather than symptoms.

Whether you're designing a new machine, troubleshooting a malfunctioning system, or exploring process improvements, our application support services deliver the technical expertise your project requires. We work collaboratively with your engineering and maintenance teams to understand your specific requirements, evaluate available options, and implement solutions that improve reliability while controlling costs.

Comprehensive Technical Product Selection

Selecting the optimal components for industrial automation applications requires deep knowledge of product capabilities, application requirements, and system integration considerations. Our technical product selection services help you navigate the thousands of available automation components to identify solutions that match your specific performance requirements, environmental conditions, and budget constraints.

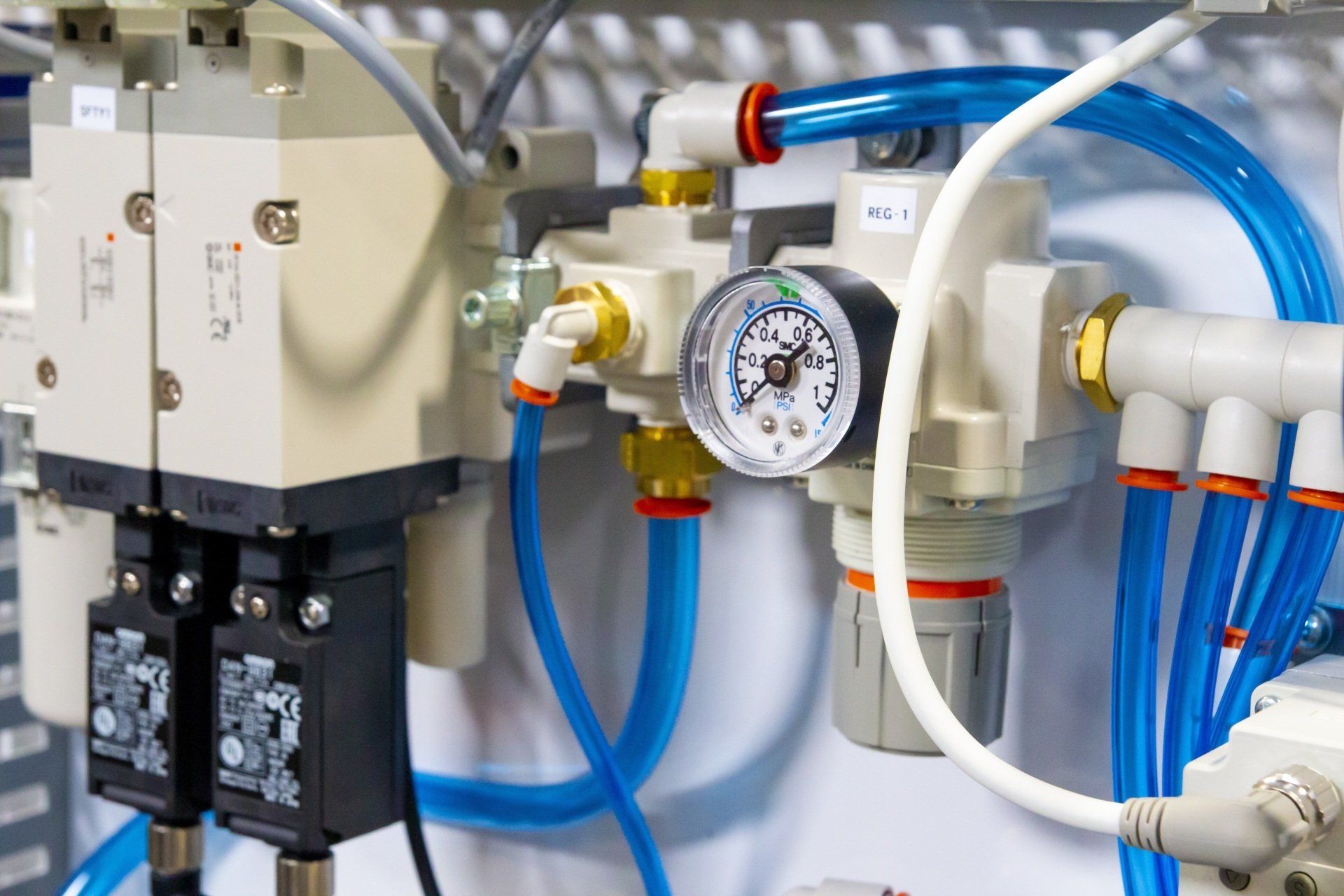

Our engineers maintain relationships with leading automation component manufacturers including SMC, Continental, Sheffer, and Stauff for pneumatics and hydraulics, along with Omron, Wago, and Sprecher and Schuh for control systems. This broad manufacturer knowledge enables us to recommend products based on performance characteristics rather than brand loyalty, ensuring you receive the most appropriate solution for your application.

The technical product selection process begins with understanding your application requirements in detail. We evaluate factors including operating pressures, flow rates, cycle times, environmental conditions, maintenance accessibility, and integration with existing systems. This thorough analysis ensures component recommendations that perform reliably in your specific operating environment.

Component compatibility represents a critical consideration in product selection for industrial automation systems. Our engineers verify that recommended components integrate properly with your existing control systems, communication protocols, and mechanical interfaces. This attention to compatibility details prevents costly installation delays and performance issues that arise from component mismatches.

Energy efficiency considerations influence many modern automation component selections. Our technical application assistance includes evaluating energy consumption characteristics of alternative components and recommending solutions that reduce operating costs while maintaining required performance levels. These efficiency improvements often generate measurable returns on investment through reduced utility costs and extended component life.

Ask an Expert

Have questions about optimizing your automation systems or need assistance with component selection? Our experienced engineers are ready to discuss your specific application challenges and recommend solutions that improve performance and reliability.

On-Site Evaluation and Process Analysis

Remote troubleshooting and technical support provide value for many situations, but complex automation challenges often require direct observation and hands-on evaluation. Our on-site evaluation services bring experienced engineers to your facility to develop detailed understanding of your machines, processes, and technical challenges through direct observation and measurement.

On-site evaluations typically begin with safety briefings and facility orientation to ensure our engineers understand your operational protocols and safety requirements. We then conduct systematic observation of the equipment or process in question, taking measurements, documenting operating conditions, and interviewing operators and maintenance personnel who work with the system daily.

The value of on-site evaluation extends beyond simple troubleshooting to include process optimization opportunities that may not be apparent without direct observation. Our engineers often identify efficiency improvements, safety enhancements, or reliability upgrades that deliver significant operational benefits beyond addressing the immediate concern that prompted the evaluation visit.

Documentation produced during on-site evaluations provides lasting value for your engineering and maintenance teams. We deliver detailed reports that include system diagrams, measurement data, component specifications, and recommended improvements with supporting technical justification. This documentation supports internal project approvals and provides reference information for future maintenance activities.

Follow-up support after on-site evaluations ensures successful implementation of recommended solutions. Our engineers remain available to answer questions during parts ordering, provide installation guidance, and verify proper system operation after modifications are completed. This comprehensive support approach reflects our commitment to delivering results rather than simply providing recommendations.

Manufacturing Application Engineering Expertise

Modern manufacturing operations incorporate increasingly sophisticated automation technologies that require specialized engineering knowledge for optimal implementation. Our manufacturing application engineering services provide the technical expertise needed to design, specify, and integrate automation solutions that improve production efficiency, product quality, and operational safety.

Application engineering support for new equipment design helps you avoid costly mistakes during the specification and procurement process. Our engineers review design concepts, recommend appropriate automation components, and identify potential integration challenges before equipment orders are placed. This proactive approach prevents expensive redesign activities and installation delays that occur when application requirements are not fully understood during initial design phases.

Retrofitting existing equipment with updated automation technology requires careful analysis of mechanical constraints, electrical capacity, and control system compatibility. Our team evaluates retrofit opportunities systematically, identifying solutions that deliver meaningful performance improvements while respecting budget limitations and minimizing production interruptions during implementation.

System integration challenges frequently arise when connecting new automation equipment to existing plant control systems. Our engineers assist with communication protocol selection, network architecture design, and interface programming requirements. We coordinate with control system integrators and equipment manufacturers to ensure seamless integration that preserves existing functionality while adding new capabilities.

Training support for your maintenance and operations personnel ensures long-term success of automation system implementations. We provide hands-on instruction covering system operation, routine maintenance procedures, and basic troubleshooting techniques. This knowledge transfer helps your team maintain system performance and resolve minor issues without requiring external support for every technical question.

Pneumatic and Hydraulic System Application Support

Pneumatic and hydraulic systems power essential manufacturing processes across New England industries. Our specialized automation component selection expertise in fluid power technologies helps you optimize actuator sizing, valve selection, and circuit design for improved system performance and reliability.

Pneumatic system applications require careful analysis of air consumption, operating pressures, and actuator force requirements to ensure adequate system capacity. Our engineers calculate flow requirements, size air preparation equipment, and recommend component specifications that deliver required performance while minimizing energy consumption and operating costs.

Hydraulic system design demands attention to pressure ratings, flow characteristics, and heat generation considerations. We assist with hydraulic power unit sizing, valve selection, and circuit design to ensure your hydraulic systems operate reliably under demanding industrial conditions. Our experience with high-pressure hydraulic applications in manufacturing environments enables us to recommend solutions that balance performance requirements with safety considerations.

Circuit optimization for existing pneumatic and hydraulic systems often reveals opportunities to improve efficiency, reduce cycle times, or enhance safety. Our engineers analyze system operation, identify bottlenecks or inefficiencies, and recommend circuit modifications that deliver measurable performance improvements. These optimization projects typically generate returns on investment through increased production rates or reduced maintenance requirements.

Component obsolescence presents ongoing challenges for maintaining older pneumatic and hydraulic equipment. Our extensive product knowledge and manufacturer relationships enable us to identify suitable replacement components when original parts become unavailable. We evaluate form, fit, and function requirements to recommend alternatives that maintain system performance while ensuring long-term parts availability.

Electrical Control System Technical Assistance

Control system integration and programming represent critical elements of modern automation implementations. Our technical application assistance for electrical control systems helps you navigate the complexities of PLC programming, HMI design, and industrial communication networks to achieve reliable automation performance.

Control panel design support ensures your electrical systems meet UL 508A requirements while accommodating specific application needs. Our engineers review electrical load calculations, specify appropriate components, and recommend panel layouts that facilitate maintenance access and future modifications. This comprehensive approach to control system design prevents problems that arise from inadequate electrical capacity or poor component selection.

PLC program review services provide valuable verification that control logic implements required safety interlocks, follows industry best practices, and includes adequate error handling. Our engineers examine program structure, identify potential issues, and recommend improvements that enhance system reliability and maintainability. This technical review process helps prevent costly programming errors that could compromise production or safety.

HMI interface design significantly influences operator effectiveness and system usability. We provide guidance on screen layout, alarm management, and data visualization to create operator interfaces that present information clearly and support efficient decision-making. Well-designed HMI systems reduce operator errors and accelerate training for new personnel.

Industrial network troubleshooting requires systematic analysis of communication protocols, network architecture, and device configuration. Our engineers use appropriate diagnostic tools to identify communication failures, resolve network performance issues, and optimize system response times. This specialized expertise helps maintain reliable data exchange between automation components and plant-wide control systems.

Collaborative Engineering Approach

Our application support methodology emphasizes collaboration with your engineering and maintenance teams throughout every engagement. We recognize that you understand your processes and operational requirements better than any outside consultant possibly could. Our role involves combining your process knowledge with our technical expertise to develop solutions that address your specific needs effectively.

Project communication protocols ensure all stakeholders remain informed throughout application support engagements. We provide regular progress updates, promptly address questions or concerns, and maintain detailed documentation of technical decisions and recommendations. This transparent communication approach builds confidence and ensures alignment between our engineering recommendations and your operational requirements.

Long-term partnership relationships develop naturally when manufacturers experience consistent value from technical support services. Many of our application support clients maintain ongoing relationships spanning multiple years and numerous projects. These established partnerships enable us to develop deep familiarity with your equipment, processes, and engineering preferences, resulting in increasingly effective support over time.

Request for Quote

Get detailed specifications and pricing for comprehensive application support services tailored to your manufacturing operations. We provide transparent quotes that outline project scope, timeline, and deliverables.