Contract Manufacturing Services: From Concept to Delivery

When your product development demands precision execution and your business requires cost-effective production solutions, Pearse Bertram's contract manufacturing services deliver the comprehensive support you need from start to finish. Our engineers bring 70+ years of manufacturing expertise to every project, transforming your designs into production-ready assemblies that meet the most demanding industrial specifications.

As your end-to-end manufacturing partner, we understand that outsourcing production represents a significant decision for your organization. Our team approaches each project with the technical rigor and attention to detail that experienced engineers and purchasing professionals expect. From initial component sourcing through final assembly and testing, we manage every aspect of your manufacturing process with documented quality control and transparent communication at every stage.

Located in Bloomfield, Connecticut, our ISO 9001:2015 certified facility serves manufacturers throughout New England and beyond. We combine strategic component sourcing, advanced assembly capabilities, and rigorous testing protocols to deliver complete manufacturing solutions that enable you to focus on your core competencies while we handle the complexities of production.

Our Contract Manufacturing Capabilities

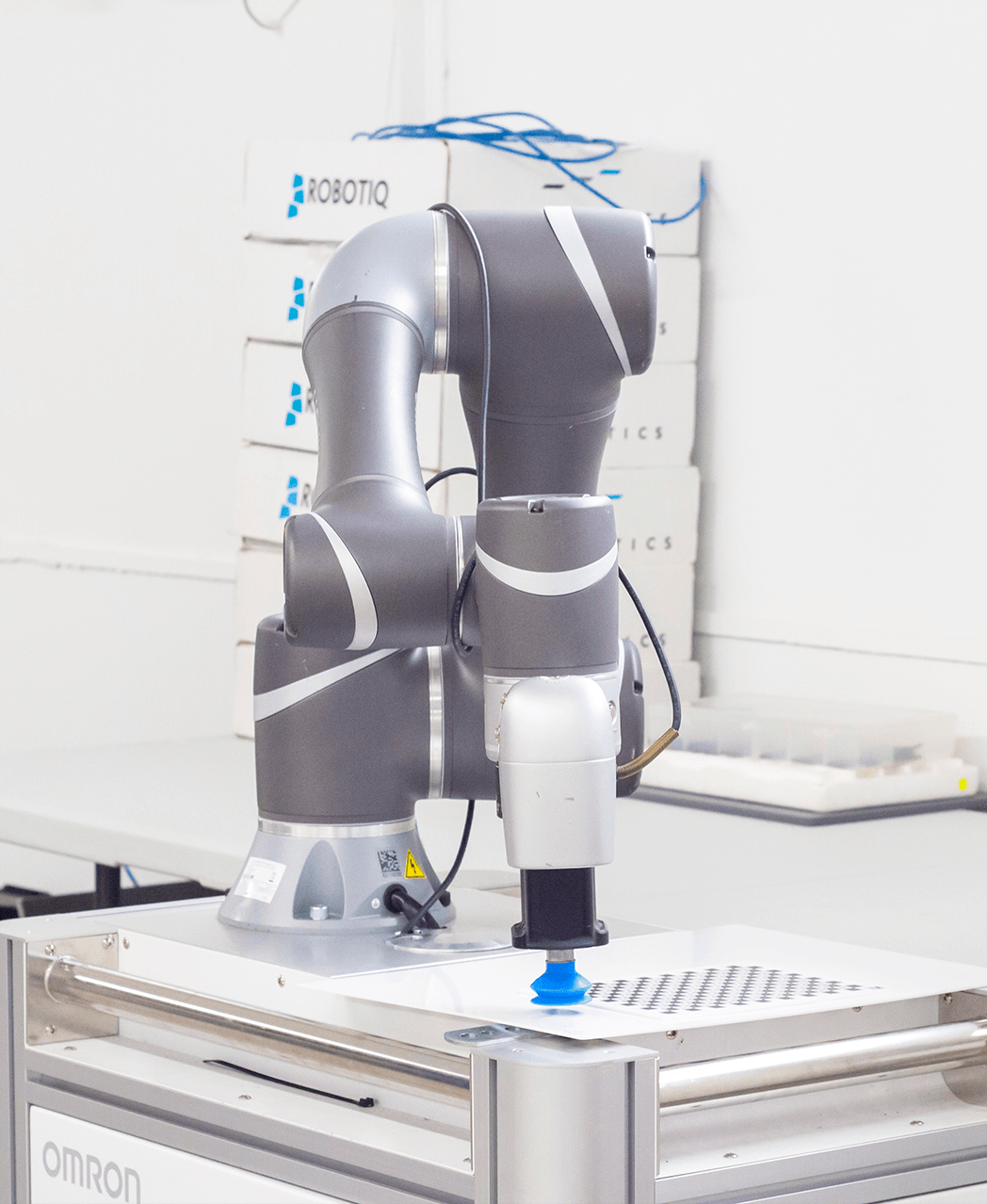

We offer comprehensive manufacturing services across multiple technical disciplines, providing integrated solutions for complex industrial assemblies:

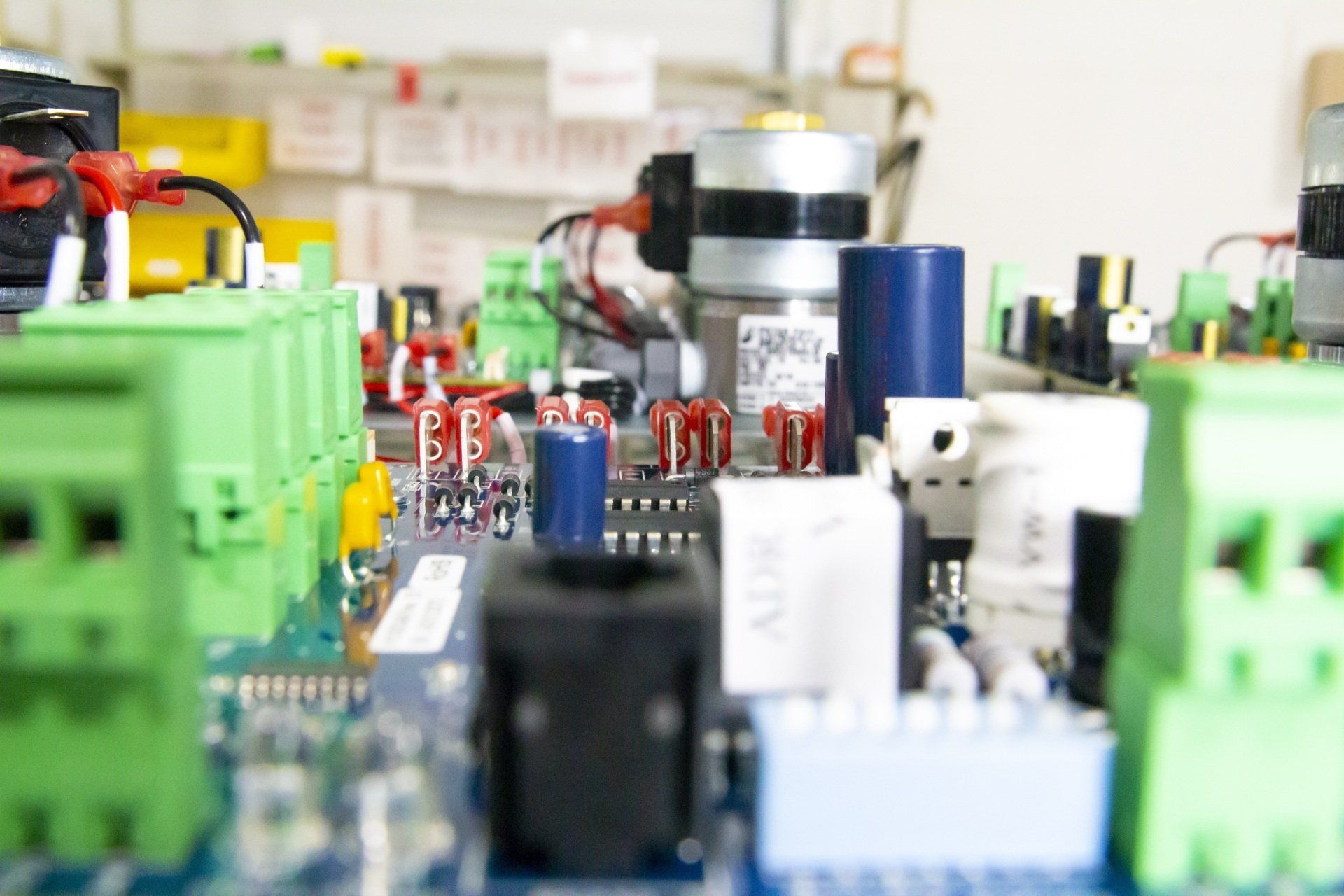

Control Panel Design & Fabrication

Custom electrical control panel design and UL 508A certified fabrication for commercial and industrial automation applications. Our engineers deliver NEMA-rated enclosures with complete documentation packages.

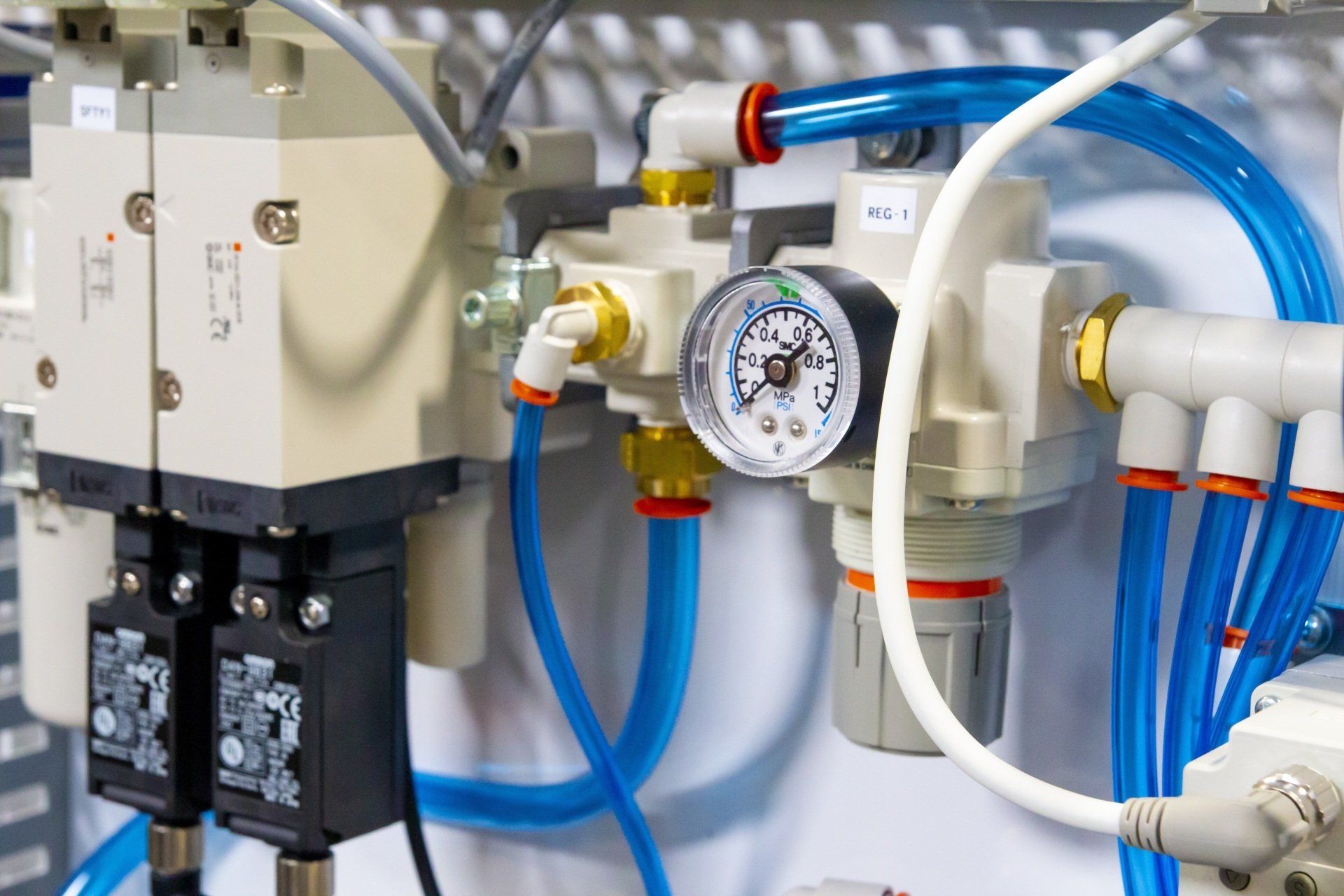

Pneumatic Systems Integration

Pneumatic system design, component assembly, and integration using proven SMC technology and industry-standard automation components for reliable, efficient operation.

Hydraulic Systems Assembly

Hydraulic power unit assembly and fluid power systems designed for demanding industrial environments requiring high force and precise control.

Ask an Expert

Our engineering team stands ready to discuss your contract manufacturing requirements and recommend optimal solutions for your specific application. We'll evaluate your designs, answer technical questions, and help you understand how our end-to-end capabilities can support your manufacturing objectives from concept through delivery.

Comprehensive Support from Start to Finish

Our contract manufacturing services extend well beyond basic assembly operations. We function as an extension of your engineering team, providing value engineering insights, design assistance, and manufacturing optimization recommendations that improve product quality while reducing overall costs. With less than 0.5% returns due to workmanship, our quality metrics demonstrate our commitment to getting every assembly right the first time.

Whether you're developing prototypes for market testing or scaling production to meet growing demand, our flexible manufacturing approach adapts to your specific requirements. We handle projects ranging from small batch manufacturing for specialized applications to higher-volume production runs, maintaining the same rigorous quality standards regardless of order size.

Value Engineering That Reduces Costs

Before production begins, our engineers analyze your bill of materials and product design to identify opportunities for cost reduction and performance improvement. We leverage our established relationships with industrial component suppliers to source high-quality materials at competitive prices, enabling us to recommend alternative components that deliver equivalent or superior performance at lower costs.

This value engineering approach has helped numerous clients achieve commercial viability for products that initially appeared too expensive to manufacture profitably. By identifying unnecessary components, suggesting more cost-effective alternatives, and optimizing assembly processes, we transform manufacturing economics to support your business objectives.

Integrated Production Support Services

Our end-to-end contract manufacturing services encompass the full spectrum of production support activities:

This integrated approach eliminates the coordination challenges and quality concerns that arise when working with multiple vendors, streamlining your supply chain and reducing administrative overhead.

Quality Systems and Certifications

Our ISO 9001:2015 certification by TÜV Rheinland demonstrates our commitment to systematic quality management throughout all manufacturing operations. This internationally recognized standard ensures consistent processes, documented procedures, and continuous improvement initiatives that maintain product quality and manufacturing efficiency.

UL 508A certification for industrial control panel manufacturing provides the regulatory compliance that electrical assemblies require for commercial and industrial applications. Electrostatic discharge protected workstations and assembly cells safeguard sensitive electronic components during handling and assembly operations.

Our quality management system includes documented inspection procedures, calibrated test equipment, and comprehensive records that support your traceability requirements. Whether you need basic quality documentation or extensive validation packages for regulated industries, our systems generate the records your applications demand.

Manufacturing Partnership Models

We recognize that different organizations require different levels of manufacturing support. Some clients need complete end-to-end solutions where we manage every aspect of production from concept through delivery, while others prefer collaborative approaches that leverage their internal expertise alongside our manufacturing capabilities.

For startups and emerging companies, we provide comprehensive design assistance and manufacturing strategy development that helps bring innovative concepts to commercial reality. Our engineers evaluate your designs for manufacturability, recommend component selections that balance performance with cost, and develop assembly processes that scale efficiently as your business grows.

Established manufacturers often engage us to handle overflow production during peak demand periods or to manufacture product lines outside their core competencies. This flexible capacity model allows you to respond to market opportunities without investing in additional equipment or staff.

OEM partnerships frequently evolve from initial component sourcing relationships into comprehensive manufacturing collaborations. As we demonstrate our technical capabilities and reliability, many clients expand our role to encompass design assistance, value engineering, and complete assembly operations.

Specific Industry Standards

Our contract manufacturing services support diverse industrial sectors, each with unique technical requirements and regulatory considerations as examples:

Medical device and life sciences manufacturers benefit from our rigorous quality control, comprehensive documentation, and manufacturing processes that support FDA compliance and ISO 13485 requirements. Our experience with validation protocols and traceability systems helps clients navigate demanding regulatory environments.

Defense and aerospace applications receive the exceptional reliability, precise tolerances, and stringent quality verification these critical industries demand. We understand military specifications, aerospace standards, and the documentation requirements that accompany these applications.

Industrial equipment manufacturers benefit from our broad technical expertise across hydraulic systems, pneumatic controls, electrical assemblies, and integrated automation solutions. Our engineers understand the performance requirements and environmental challenges these applications present.

Test and measurement equipment manufacturing receives the precision assembly, careful calibration, and thorough verification procedures necessary for accurate, reliable instrumentation throughout operational life.

Geographic Advantages of New England

Being Built in the USA reduces challenges with overseas suppliers and tariffs. Our Connecticut location provides strategic advantages for manufacturers in the USA, especially those in northeastern markets. Proximity to major metropolitan areas enables responsive support, simplified logistics, and convenient on-site collaboration when complex projects require face-to-face engineering discussions.

New England's established manufacturing infrastructure and skilled workforce support sophisticated production requirements. The region's concentration of precision manufacturers, technical suppliers, and engineering talent creates an ecosystem that benefits your manufacturing operations through our vetted network of suppliers, technical resources, and industry expertise.

Getting Started with Your Project

Beginning a contract manufacturing partnership starts with understanding your specific requirements, objectives, and constraints. Our engineers will review your designs, specifications, and production forecasts to develop manufacturing strategies that align with your business goals.

We provide detailed project quotes that outline manufacturing processes, component costs, assembly labor, testing procedures, and delivery schedules. This transparency helps you make informed decisions about manufacturing strategies and enables accurate financial planning for your production requirements.

Once you approve our proposal, we develop detailed manufacturing documentation including assembly procedures, inspection protocols, and testing specifications. Throughout production, we maintain open communication about project status, quality metrics, and any issues requiring attention. This collaborative approach keeps you informed while allowing our team to focus on delivering the high-quality assemblies your applications demand.

Request for Quote

Receive detailed specifications and comprehensive pricing for your contract manufacturing project. Our quotes include technical details, timeline projections, and complete scope definition to support your planning and decision-making processes.