Comprehensive Data Center Solutions for Modern Infrastructure

The explosive growth of artificial intelligence, cloud computing, and high-performance computing has transformed data centers into some of the most demanding industrial environments in operation today. As processing power increases and server densities climb, thermal management has become mission-critical. Pearse Bertram provides comprehensive solutions for data center infrastructure, combining precision fluidic cooling components with reliable electrical systems to keep critical operations running efficiently.

Our engineers understand that data center downtime costs thousands of dollars per minute. That's why we've built our data center product portfolio around proven components from industry-leading manufacturers, backed by our 70+ years of engineering expertise and contract manufacturing capabilities. Whether you're building a new hyperscale facility, upgrading cooling systems in an existing colocation center, or designing edge computing infrastructure, our team can help you select and integrate the right components for your specific thermal and electrical requirements.

Products Supporting Data Center Infrastructure

Pearse Bertram offers specialized products designed to meet the demanding requirements of modern data center cooling and electrical systems. Our portfolio includes both custom-fabricated assemblies from our Streamline contract manufacturing division and precision components from industry-leading manufacturers.

Custom Fabrication Services:

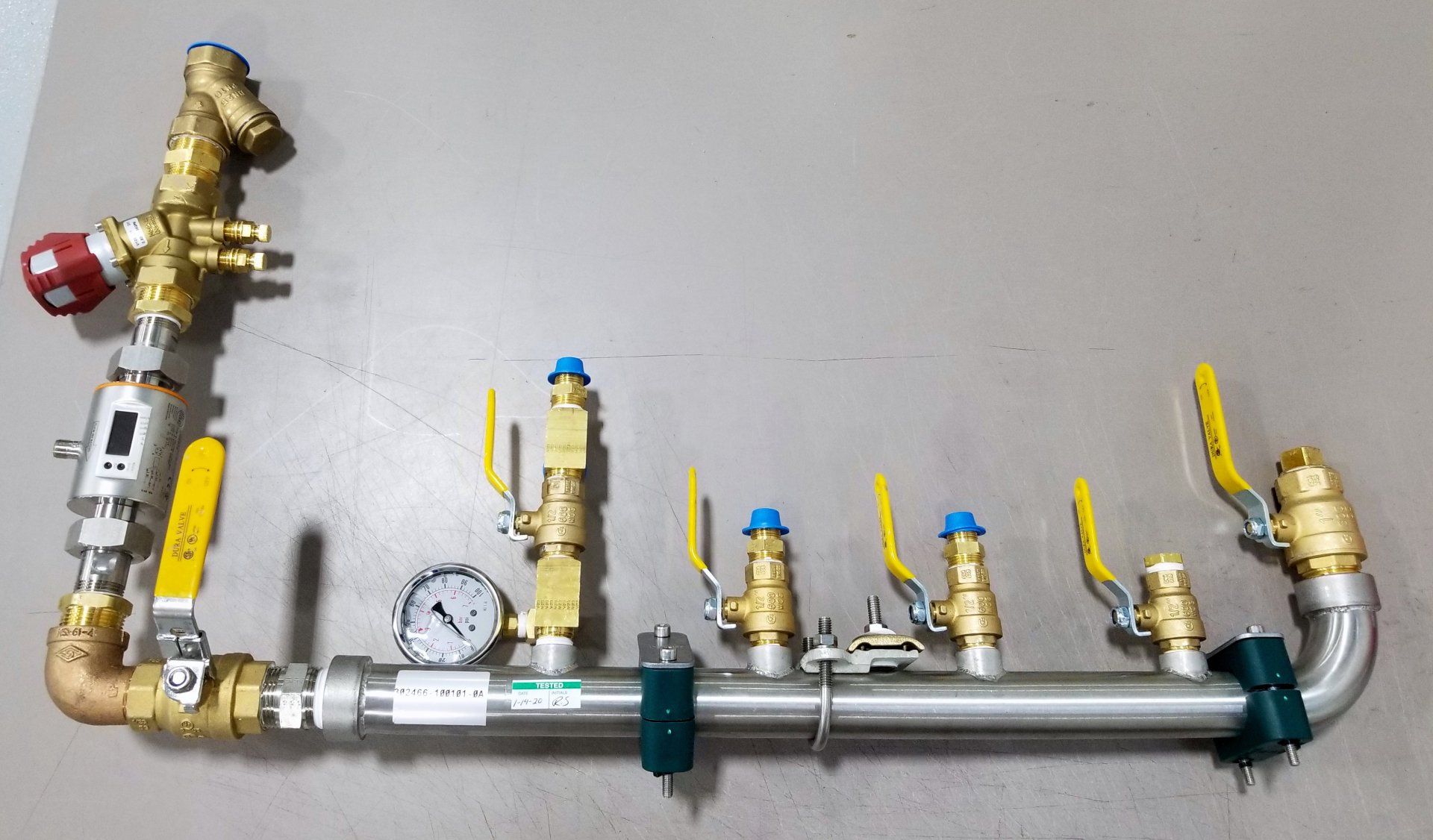

Cooling Manifolds

Custom-engineered liquid cooling distribution assemblies designed for high-density server environments

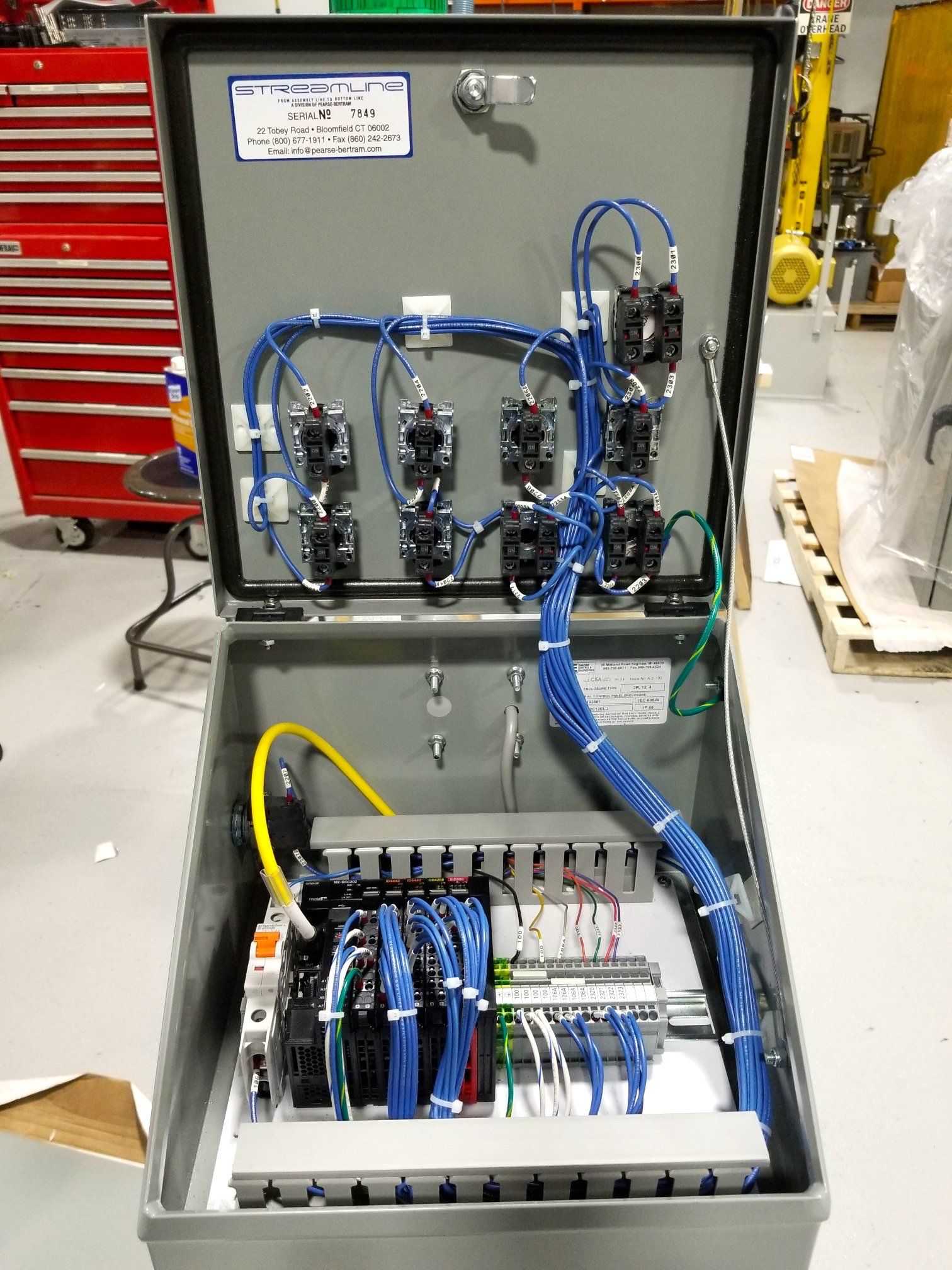

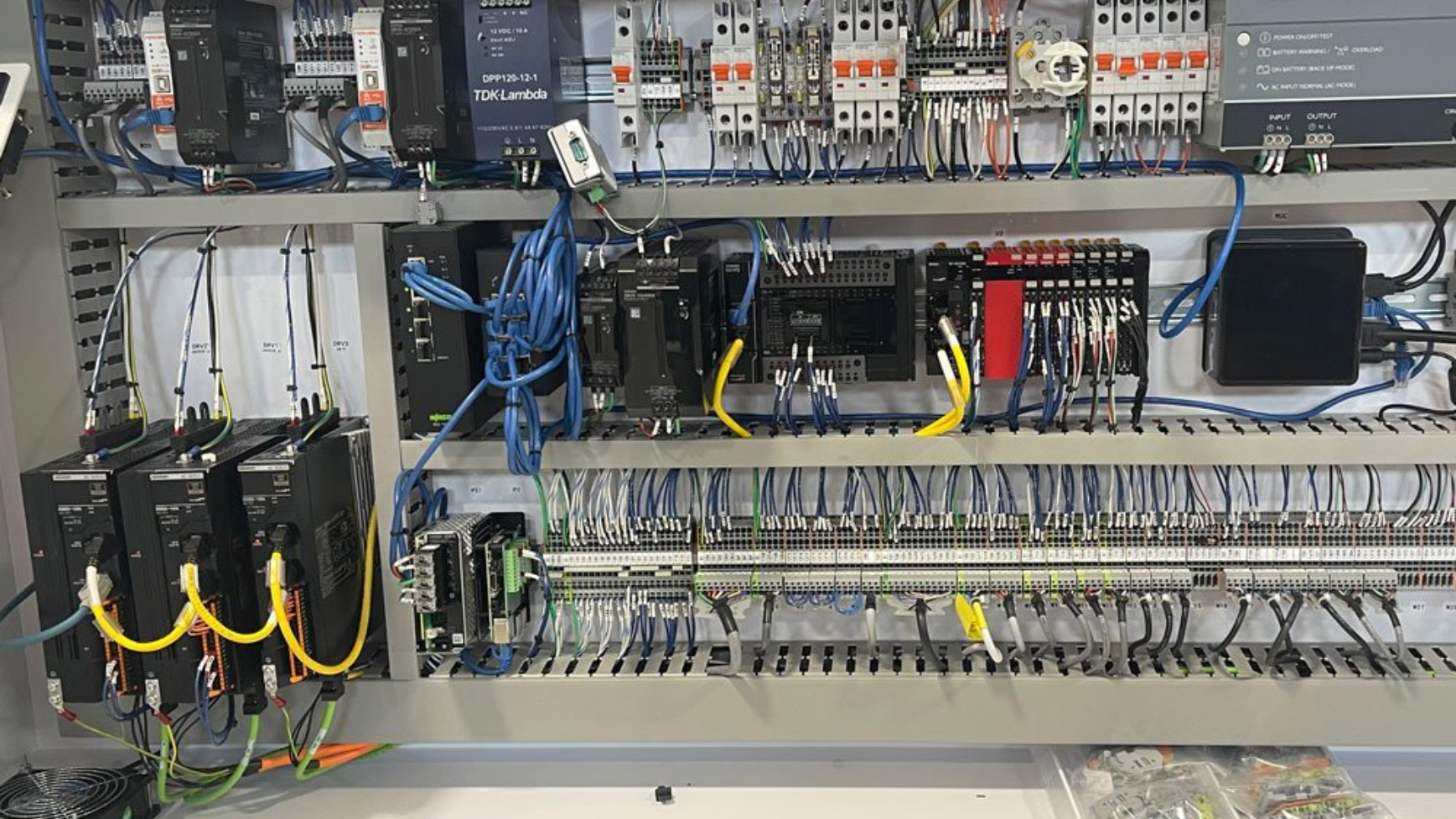

DIN Rail Assemblies

Pre-wired electrical control assemblies for cooling system integration

Electrical Box Assemblies

Complete electrical enclosures with integrated components for plug-and-play installation

Fluidic Cooling Components:

SMC Flow Sensors

Real-time flow monitoring for optimal thermal performance

SMC KK Couplers

Reliable quick-connect solutions for maintenance accessibility

Foster/Breco Colored Quick Disconnects

Tool-free, color-coded connections for error-free service

Ball Valves

Circuit isolation valves for maintenance and system segmentation

Tubing

Compatible fluid transfer lines for coolant distribution

Strainers

Particulate filtration to protect sensitive cooling components

Heat Exchangers

Thermal energy transfer equipment for facility cooling integration

Electrical and Network Components:

Wago Ethernet Switches

Industrial network connectivity for building automation systems

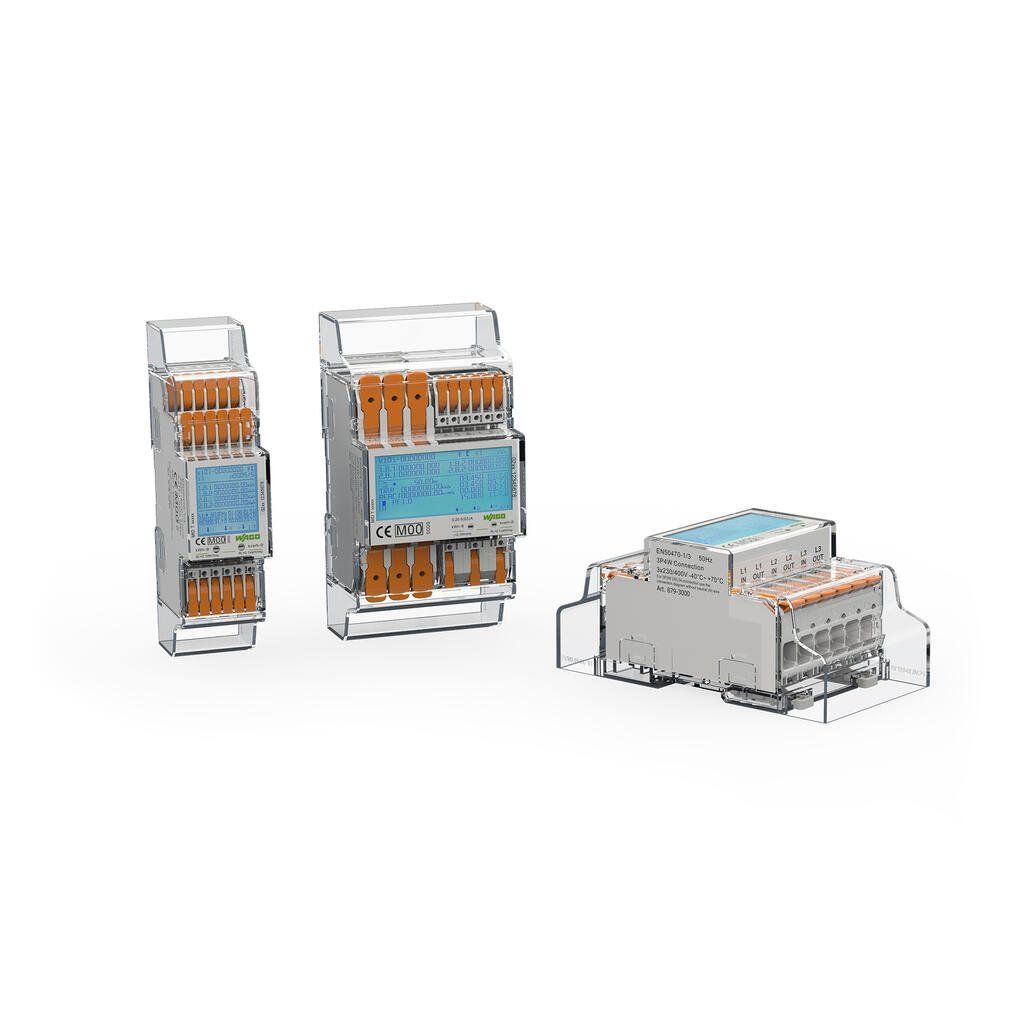

Wago Power Monitoring

Real-time electrical consumption tracking and analysis

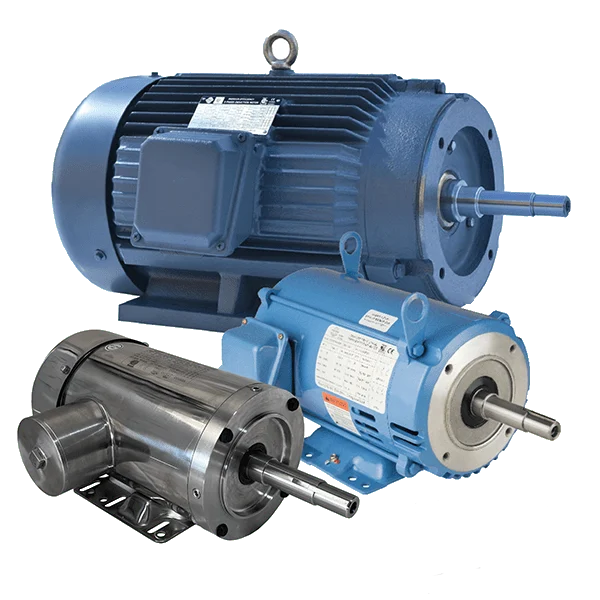

Motors

AC motors for running pumps and fans

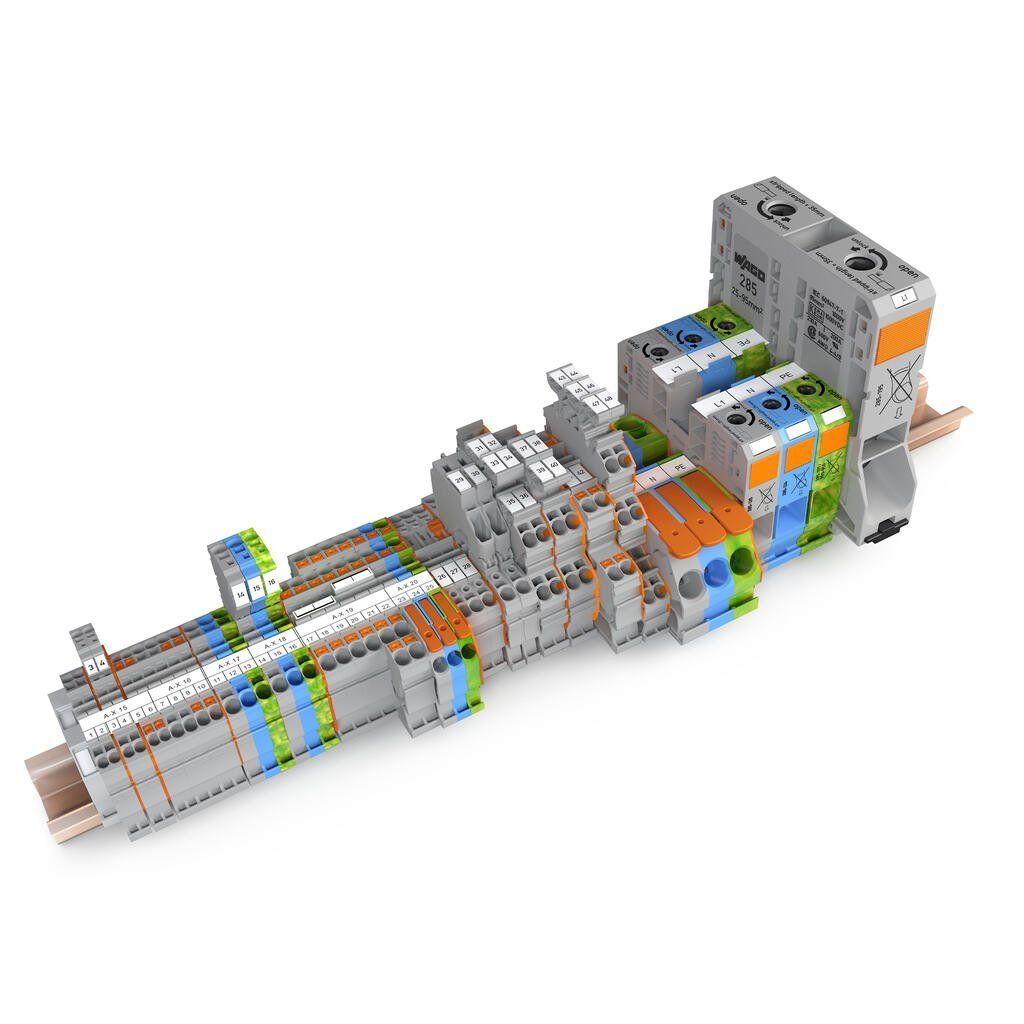

Electrical Panel Components

Terminal Blocks, Contactors, and other necessities.

Ask an Expert

Our engineers have extensive experience designing and supporting data center cooling and electrical systems. Let's discuss your specific infrastructure requirements and identify the optimal solutions for your facility.

Custom-Engineered Cooling Manifolds for Liquid Cooling Systems

Modern data centers generate tremendous heat loads that traditional air cooling cannot effectively manage. Liquid cooling has emerged as the preferred solution for high-density computing environments, offering superior thermal transfer efficiency and reduced energy consumption compared to air-based systems. Our Streamline contract manufacturing division specializes in precision cooling manifold fabrication designed specifically for data center applications.

These custom cooling manifolds distribute coolant to multiple servers or racks from a single supply line, reducing installation complexity while maintaining precise flow control. Our engineering team works with your specifications to design manifolds that optimize coolant distribution based on your rack configuration and thermal loads. We manufacture these assemblies using materials selected for compatibility with your coolant chemistry and operating conditions, ensuring long-term reliability in demanding data center environments.

Each cooling manifold undergoes comprehensive testing before shipment. We verify flow distribution across all outlets, check for leaks under operating pressure, and confirm that pressure drop meets design specifications. Complete documentation accompanies every assembly, including detailed drawings, material certifications, and test reports. This documentation supports your commissioning process and provides reference material for future maintenance activities.

Precision Fluidic Components for Optimal Thermal Management

Effective liquid cooling systems depend on carefully selected components that work together to deliver consistent thermal performance. Our fluidic cooling product line addresses every aspect of liquid cooling infrastructure, from flow control and monitoring to reliable connections and filtration.

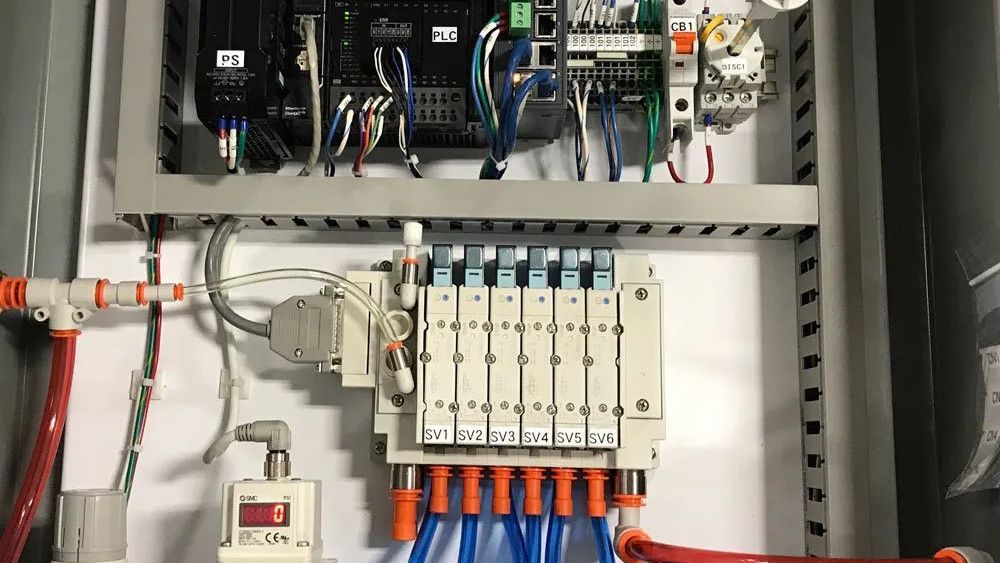

SMC JSX valves provide the precise flow control necessary for sophisticated cooling loop management. These valves maintain on/off or proportional coolant flow rates despite system pressure variations, ensuring uniform cooling across server racks. Their compact design saves valuable space in dense data center environments while delivering reliable performance under continuous operation.

Flow monitoring represents a critical capability for intelligent thermal management. SMC flow sensors deliver accurate real-time flow rate data across the typical ranges found in data center cooling loops, from individual blade server circuits to larger rack-level distribution systems. These sensors integrate seamlessly with building management systems, enabling automated flow optimization based on actual thermal loads and alerting operators to potential blockages or circulation issues before they impact cooling performance.

Quick disconnect fittings enable rapid maintenance and equipment upgrades without system downtime. Foster and Breco colored quick disconnects provide tool-free connections with visual coding that prevents incorrect connections during service activities. SMC KK couplers offer reliable, leak-free connections designed for the operating pressures and temperatures common in data center cooling applications. These fittings support various coolant types including water-glycol mixtures and dielectric fluids.

Ball valves throughout the cooling system enable isolation of individual circuits for maintenance while keeping the rest of the system operational. Our valve selection includes appropriately sized options for different loop configurations, from small branch circuits to main distribution lines. Proper valve placement in your cooling infrastructure minimizes the scope of shutdowns required for routine maintenance.

Strainers protect sensitive cooling components from particulate contamination that can reduce heat transfer efficiency or damage flow sensors and valve seals. Installing strainers at strategic points in your cooling loop captures debris before it reaches critical components, extending equipment life and maintaining optimal thermal performance.

Heat exchangers transfer thermal energy from server cooling loops to facility chilled water systems or dry coolers. Our heat exchanger selection includes options appropriate for different capacity requirements and temperature approaches, helping you achieve target supply temperatures while maximizing energy efficiency.

Tubing forms the circulatory system that connects all these components into a functional cooling infrastructure. We supply tubing materials compatible with your coolant chemistry and operating conditions, available in sizes appropriate for everything from individual server connections to main distribution headers.

Electrical Assemblies and Power Management Solutions

Reliable electrical infrastructure forms the foundation of data center operations. Our Streamline contract manufacturing division fabricates custom electrical assemblies for data center applications, while our distribution business provides advanced networking and power monitoring components from industry-leading manufacturers.

DIN rail assemblies provide organized, accessible electrical distribution for cooling system controls and monitoring equipment. These assemblies integrate terminal blocks, circuit protection devices, and control relays into compact packages that mount easily in control panels or equipment racks. Our engineers work with your electrical specifications to design assemblies that meet code requirements while optimizing panel space utilization.

Electrical box assemblies house control components in appropriately rated enclosures for different data center zones. These assemblies arrive at your facility pre-wired and tested, reducing installation time and eliminating field wiring errors. Whether you need NEMA-rated enclosures for outdoor equipment yards or standard indoor boxes for controlled environments, we can fabricate assemblies that match your specific requirements.

Wago Ethernet switches enable network connectivity for cooling system monitors, building automation controllers, and other smart devices throughout your data center infrastructure. These industrial-grade switches provide reliable communication in the temperature and humidity conditions typical of data center environments. Managed switch options support network segmentation and quality-of-service features that ensure critical control traffic receives priority.

Power monitoring capabilities from Wago provide real-time visibility into electrical consumption across your data center infrastructure. These monitoring systems track voltage, current, power factor, and energy consumption at the circuit level, supporting both operational efficiency initiatives and capacity planning efforts. Integration with building management systems enables automated load balancing and alerts for abnormal consumption patterns that might indicate equipment problems. Real-time error or crash reports can be sent to techs for service and monitor brown outs or black outs for real-time reporting.

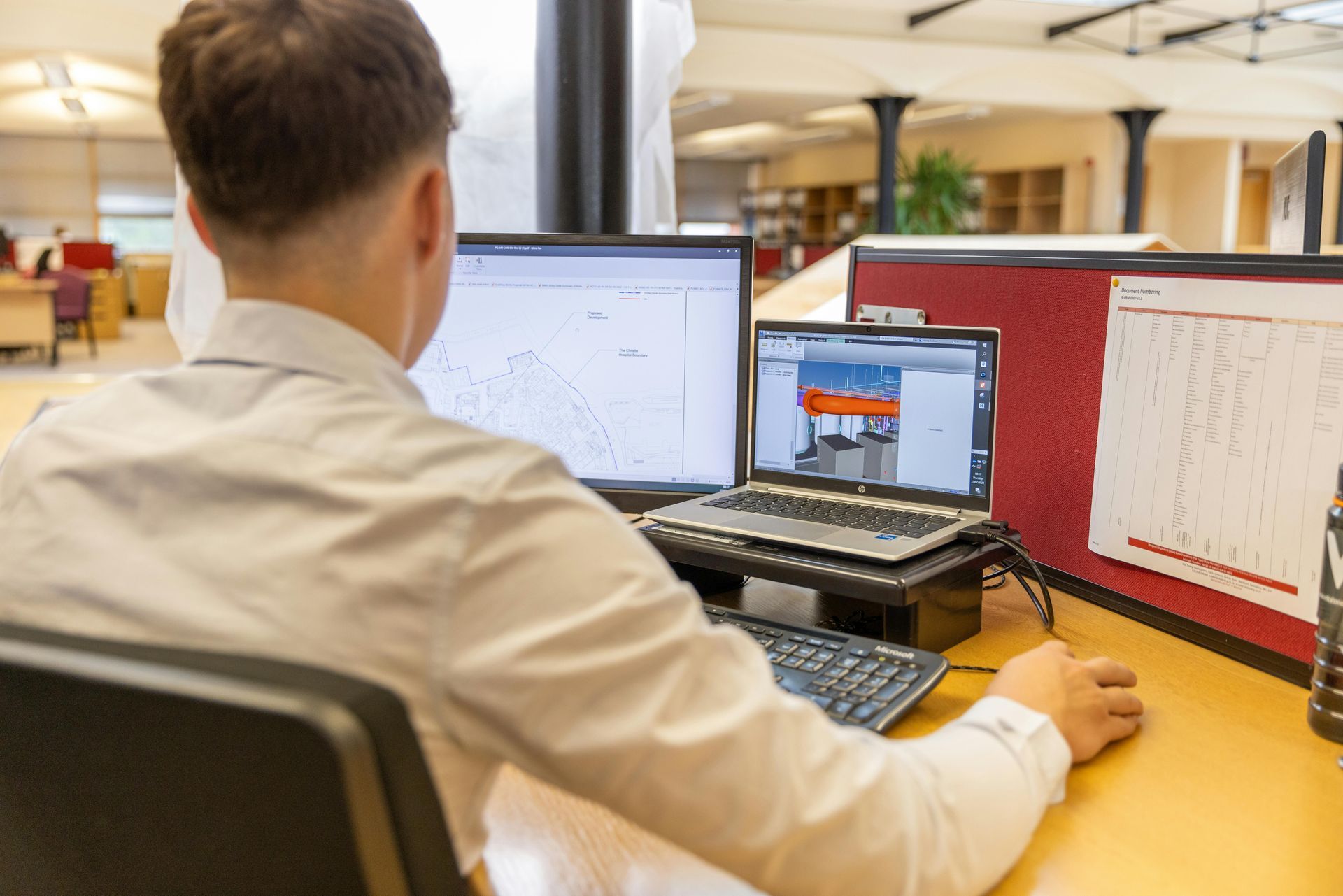

Integrated Solutions Approach for Complex Data Center Projects

Large-scale data center projects benefit from our integrated approach that combines component distribution, custom fabrication, and engineering support. Rather than sourcing cooling components from one vendor, electrical assemblies from another, and fabrication services from a third party, working with Pearse Bertram streamlines your procurement process while ensuring component compatibility across systems.

Our engineers can review your data center design during the planning phase, identifying opportunities to optimize component selection and reduce system complexity. We understand the interplay between cooling system hydraulics, electrical requirements, and operational constraints. This systems-level perspective helps you avoid specification conflicts that can emerge when different subsystems are designed in isolation.

Project management support ensures that components and assemblies arrive when you need them during construction. We coordinate delivery schedules with your general contractor's timeline, reducing on-site storage requirements and minimizing the risk of component damage before installation. Our familiarity with data center construction schedules allows us to anticipate long-lead items and recommend early procurement for critical components.

Technical Support Throughout Your Data Center Lifecycle

Our relationship with data center operators extends beyond initial equipment supply. Technical support remains available throughout your facility's operational life to address questions, help troubleshoot issues, and assist with expansion projects. Our engineers understand that data center operations run around the clock, and we provide responsive support that respects the urgency of your operational requirements.

Replacement parts availability represents a critical concern for data center operators. We maintain inventory of common components used in cooling and electrical systems, enabling rapid replacement when failures occur. For specialized items, we leverage our manufacturer relationships to expedite procurement and minimize downtime. Preventive maintenance support includes recommendations for inspection intervals and replacement criteria based on manufacturer specifications and our experience with similar installations.

As your data center evolves, our team can help evaluate new technologies and components that might improve efficiency or capacity. Retrofitting existing facilities with newer cooling technologies or upgrading electrical systems to support higher power densities requires careful planning to avoid disrupting ongoing operations. We work with you to develop implementation strategies that minimize operational impact while achieving your upgrade objectives.

Request for Quote

Get detailed specifications and pricing for data center components and custom assemblies. We provide comprehensive quotes including technical details, delivery timelines, and complete project scope.