Custom Machine Design Services

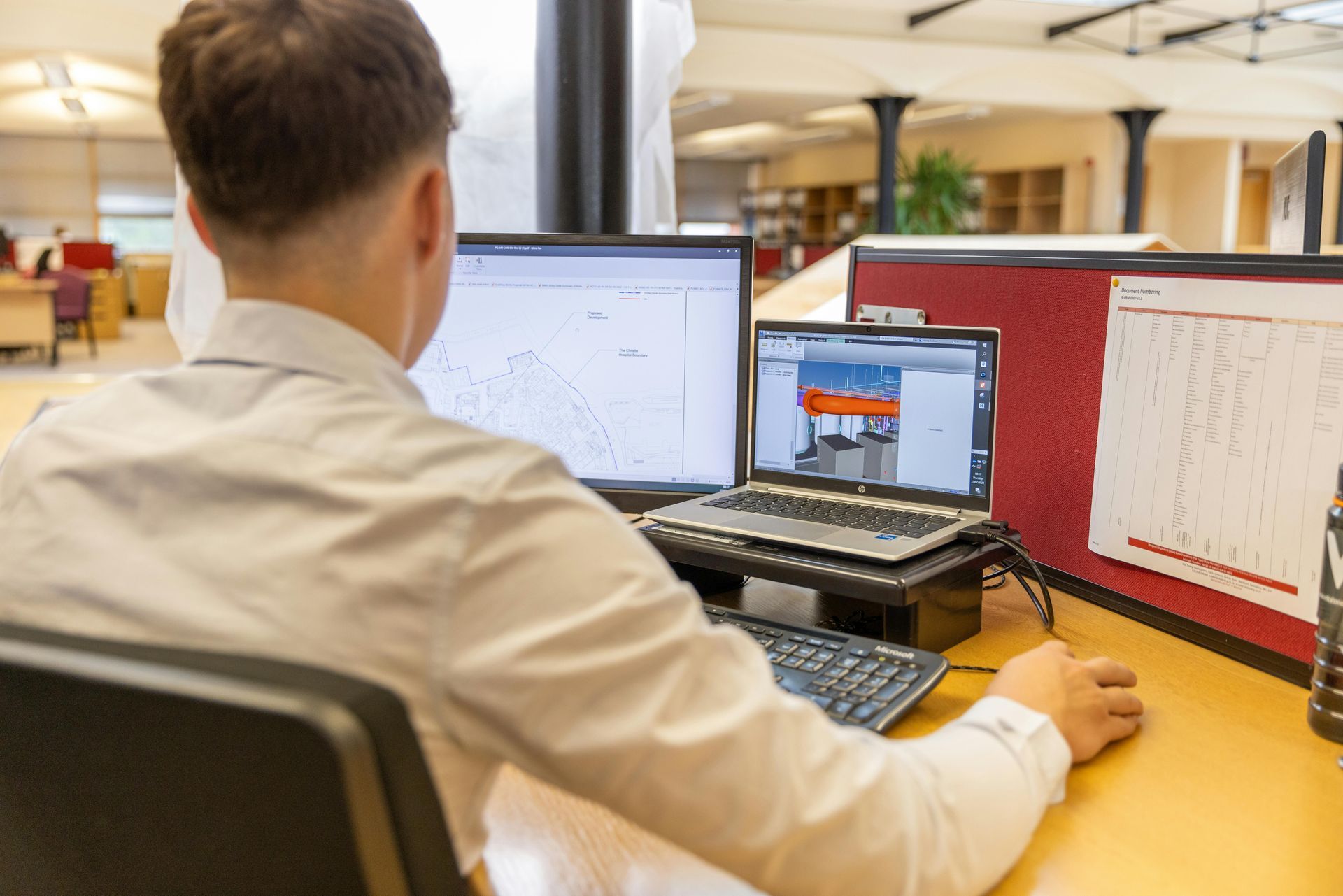

When your manufacturing operation requires specialized equipment that off-the-shelf solutions cannot provide, Pearse Bertram's custom machine design services deliver engineered systems tailored to your exact production requirements. Our CAD-certified engineers bring 70+ years of manufacturing expertise to every project, transforming initial concepts into fully operational machines that improve efficiency, quality, and throughput in demanding industrial environments.

Our team understands that successful machine design services require more than technical drawings and component specifications. We approach every project as a partnership, working closely with your engineers to understand operational challenges, space constraints, and performance objectives before developing solutions that integrate seamlessly with your existing processes. This consultative methodology ensures the machines we design and build meet both immediate production needs and long-term operational goals.

Complete Engineering Support from Concept Through Commissioning

Our machine design services encompass the entire project lifecycle, providing comprehensive support whether you're starting with preliminary sketches or need assistance completing partially developed designs. We handle every technical aspect of custom machine design, from initial feasibility analysis through CAD documentation, component selection, fabrication, assembly, testing, and final commissioning at your facility.

The foundation of effective industrial machine design lies in thorough requirements analysis and careful consideration of operational realities. Our engineers conduct detailed on-site evaluations of your manufacturing processes, identifying opportunities for automation, efficiency improvements, and quality enhancements that inform the design approach. This hands-on assessment ensures we design machines that address actual production challenges rather than theoretical requirements.

Our engineering team maintains proficiency across multiple disciplines including mechanical design, electrical systems, pneumatic and hydraulic integration, and automation control programming. This broad technical capability allows us to design complete turnkey systems rather than individual components, reducing integration complexities and ensuring optimal performance of the finished machine.

Ask an Expert

Have questions about your machine design project? Our experienced engineers are ready to discuss your specific manufacturing challenges and recommend solutions that improve productivity and efficiency.

Specialized Machine Engineering Across Multiple Industries

Our machine design services support diverse industrial applications, each requiring specific technical knowledge and regulatory understanding. We design machines for pharmaceutical manufacturing that meet cGMP requirements, food processing equipment that complies with USDA standards, and industrial automation systems that integrate with existing plant infrastructure. This industry-specific expertise ensures your custom machine meets all applicable codes and standards.

For medical device and pharmaceutical manufacturing clients, our engineers design machines that facilitate FDA validation processes, incorporating design features that support cleaning validation, equipment qualification, and batch record requirements. We understand cleanroom compatibility requirements and design machines using appropriate materials and construction techniques for controlled environments.

Manufacturing engineering projects for food and beverage processing demand specialized knowledge of sanitary design principles, washdown requirements, and HACCP considerations. Our team designs machines using food-grade materials, smooth surfaces that minimize bacterial growth, and construction techniques that enable thorough cleaning. We incorporate proper drainage, eliminate crevices that could harbor contaminants, and ensure all product-contact surfaces meet FDA material requirements.

Industrial equipment manufacturers benefit from our experience designing automation systems that improve production speed, enhance quality consistency, and reduce labor requirements. We design machines that integrate with existing material handling systems, incorporate vision inspection capabilities, and provide comprehensive data collection for process monitoring and optimization.

Comprehensive Fabrication and Assembly Services

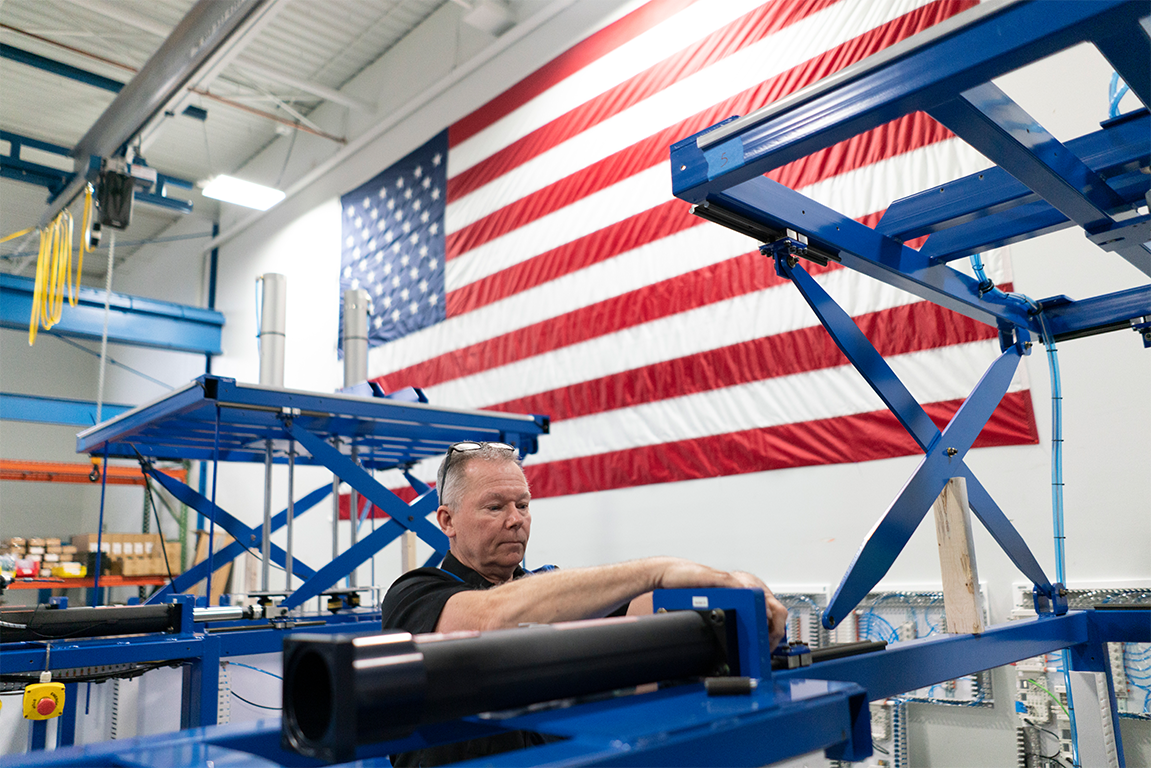

Our machine design services include complete fabrication and assembly capabilities, ensuring the machines we engineer are built to exacting standards. We source custom metal components, assemble purchased parts, integrate electrical control systems, and perform comprehensive testing before delivery. This integrated approach eliminates coordination challenges associated with managing multiple vendors and ensures accountability throughout the project.

Electrical control panel design and fabrication represents a core capability within our machine engineering services. We design UL 508A certified control panels incorporating the appropriate PLC platforms, HMI interfaces, and communication networks for your application. Our engineers handle all aspects of panel design including circuit design, component layout, wire routing, and programming.

Pneumatic and hydraulic system integration forms another essential element of many machine designs. We design complete fluid power systems including actuator selection, valve manifold design, power unit sizing, and control circuit development. Our engineers understand the practical aspects of pneumatic and hydraulic systems, designing for reliable operation, ease of maintenance, and optimal performance.

Comprehensive Fabrication and Assembly Services

Our machine design services include complete fabrication and assembly capabilities, ensuring the machines we engineer are built to exacting standards. We source custom metal components, assemble purchased parts, integrate electrical control systems, and perform comprehensive testing before delivery. This integrated approach eliminates coordination challenges associated with managing multiple vendors and ensures accountability throughout the project.

Electrical control panel design and fabrication represents a core capability within our machine engineering services. We design UL 508A certified control panels incorporating the appropriate PLC platforms, HMI interfaces, and communication networks for your application. Our engineers handle all aspects of panel design including circuit design, component layout, wire routing, and programming.

Pneumatic and hydraulic system integration forms another essential element of many machine designs. We design complete fluid power systems including actuator selection, valve manifold design, power unit sizing, and control circuit development. Our engineers understand the practical aspects of pneumatic and hydraulic systems, designing for reliable operation, ease of maintenance, and optimal performance.

Request for Quote

Get detailed specifications and project estimates for your custom machine design. We provide comprehensive proposals including technical details, timeline, and complete project scope.