Expert Pneumatic Assembly and System Design Services

When your manufacturing operation or machinery requires cost-effective motion control, rapid cycle times, and reliable performance, professional pneumatic assembly services provide the proven solution your business needs. Pearse Bertram combines 90+ years of New England engineering expertise with comprehensive pneumatic capabilities to deliver custom-engineered systems that optimize your automation processes.

Our team of experienced engineers understands that successful pneumatic systems depend on more than just component selection. From initial concept through final commissioning, we provide complete pneumatic system design services that address your specific application requirements, environmental conditions, and performance objectives. Whether you need a simple actuator assembly or a complex multi-station pneumatic panel, our consultative approach ensures your system delivers the speed, accuracy, and reliability your operation demands.

As a premier distributor of SMC pneumatic components, we combine world-class product quality with local engineering support and rapid response capabilities. This partnership enables us to design and fabricate pneumatic solutions that leverage proven technology while meeting the unique demands of New England manufacturing environments.

Comprehensive Pneumatic Design and Fabrication Capabilities

Our pneumatic assembly services span the complete project spectrum, from component selection assistance to turnkey system design and fabrication. We work closely with your engineering and maintenance teams to understand your automation challenges, cycle time requirements, and operational constraints before recommending solutions that balance performance with cost-effectiveness.

The foundation of effective pneumatic system design lies in thorough application analysis and careful component selection. Our engineers evaluate your force requirements, stroke lengths, cycle rates, and environmental factors to specify actuators, valves, and control components that optimize system performance. We design circuits that incorporate proper air preparation, speed control, safety interlocks, and diagnostic capabilities. This comprehensive approach to system design reduces troubleshooting time and simplifies maintenance activities throughout your equipment's operational life.

Ask an Expert

Have questions about pneumatic assembly for your specific application? Our experienced engineers are ready to discuss your automation requirements and recommend solutions that optimize performance.

Custom Pneumatic Panel Builder Services

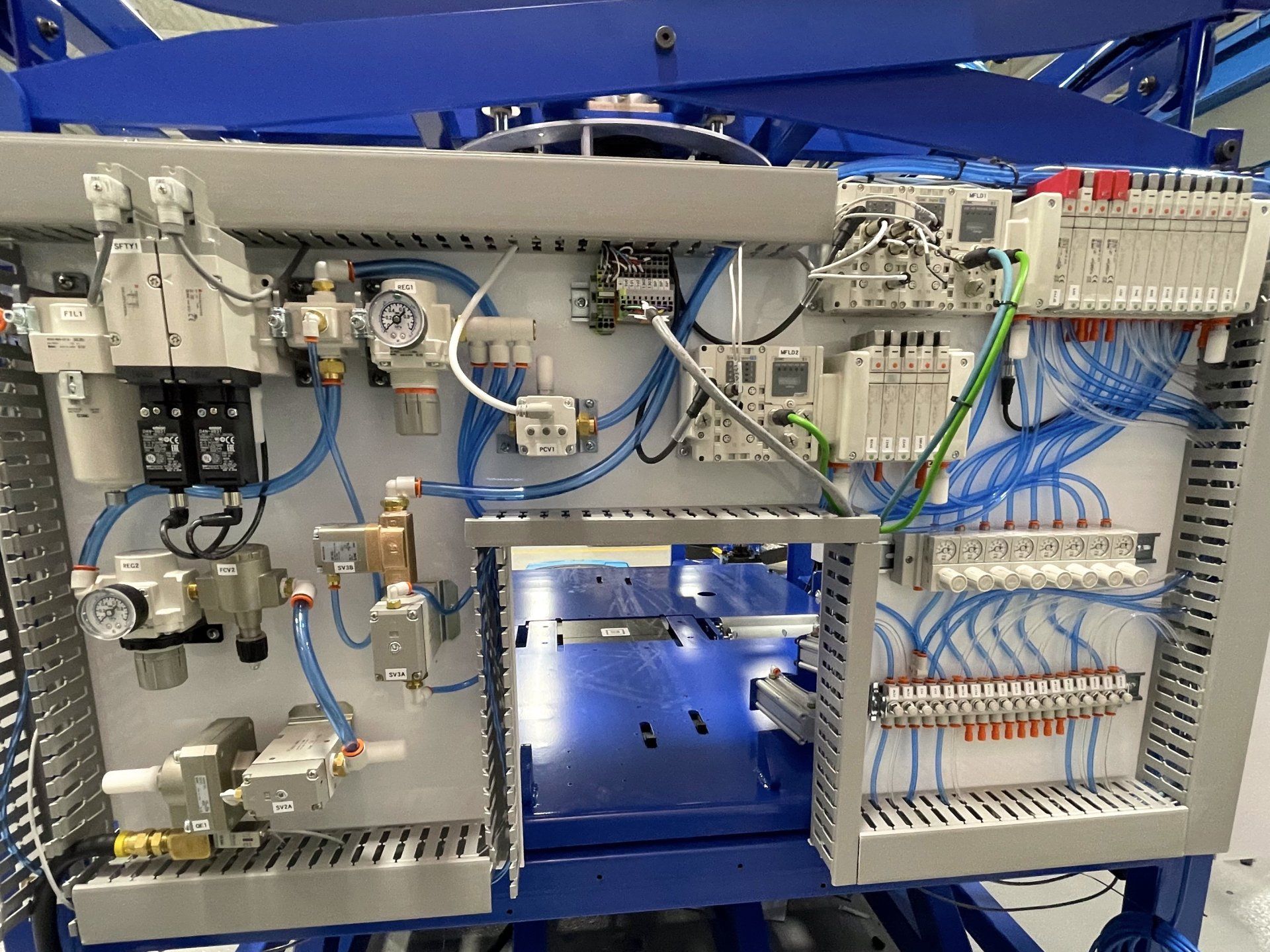

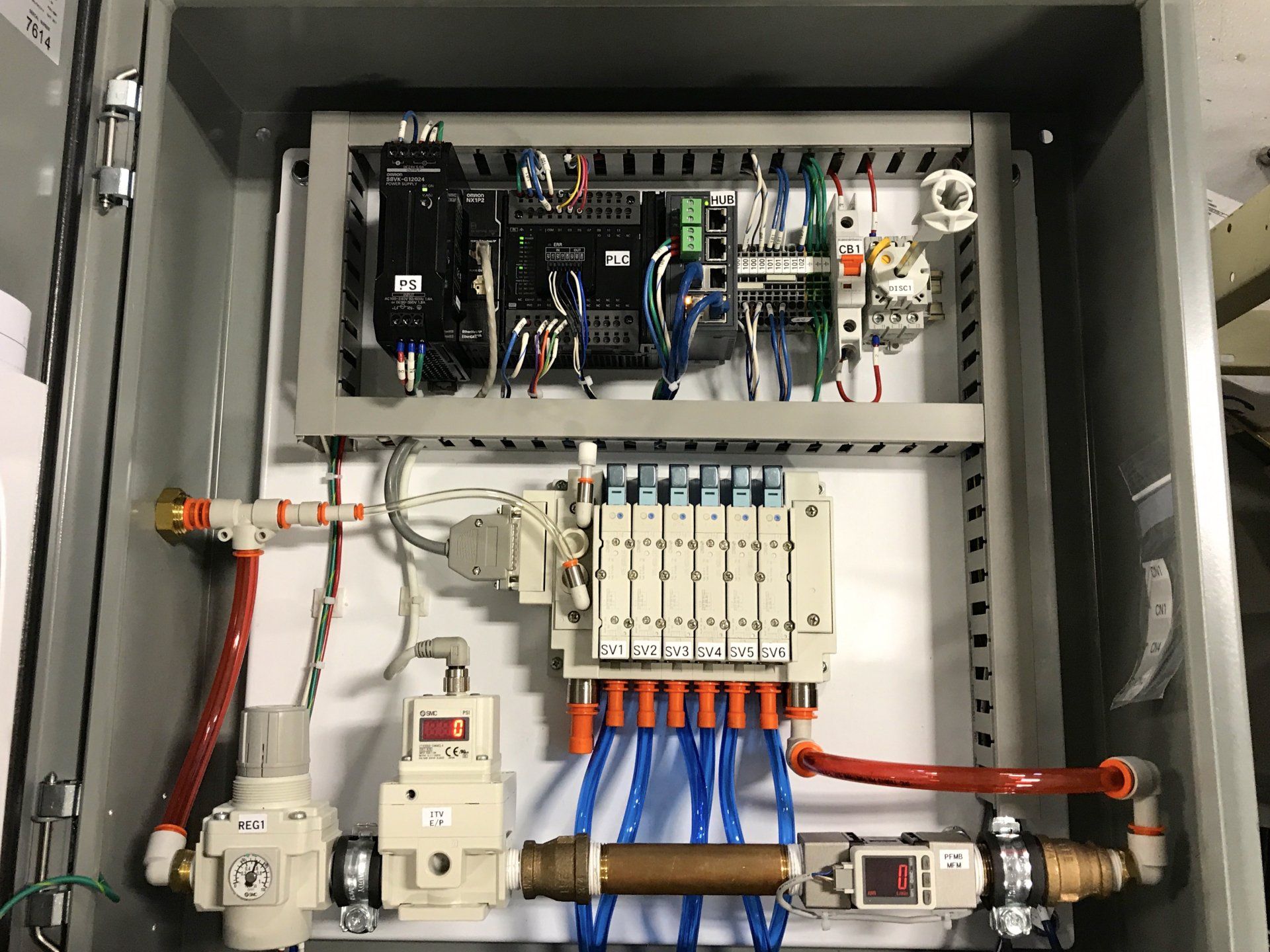

Complex automation systems often require centralized pneumatic control through custom-designed panels that consolidate valves, manifolds, and control components in organized, accessible configurations. As an experienced custom pneumatic panel builder, we design and fabricate panels that optimize space utilization while maintaining clear component identification and service accessibility.

Our pneumatic panel designs incorporate proven layout principles that simplify installation and reduce maintenance downtime. We organize valve banks logically, implement consistent labeling systems, and provide clear documentation that helps your maintenance team quickly identify components and troubleshoot issues. Panel enclosures are selected based on your environmental conditions, with options ranging from standard industrial enclosures to NEMA 4X rated panels for washdown environments.

Integration capabilities extend to electrical controls, with panels designed to accommodate PLC outputs, pressure switches, and diagnostic sensors. Our engineers coordinate pneumatic and electrical requirements to create integrated control solutions that streamline installation and reduce system complexity.

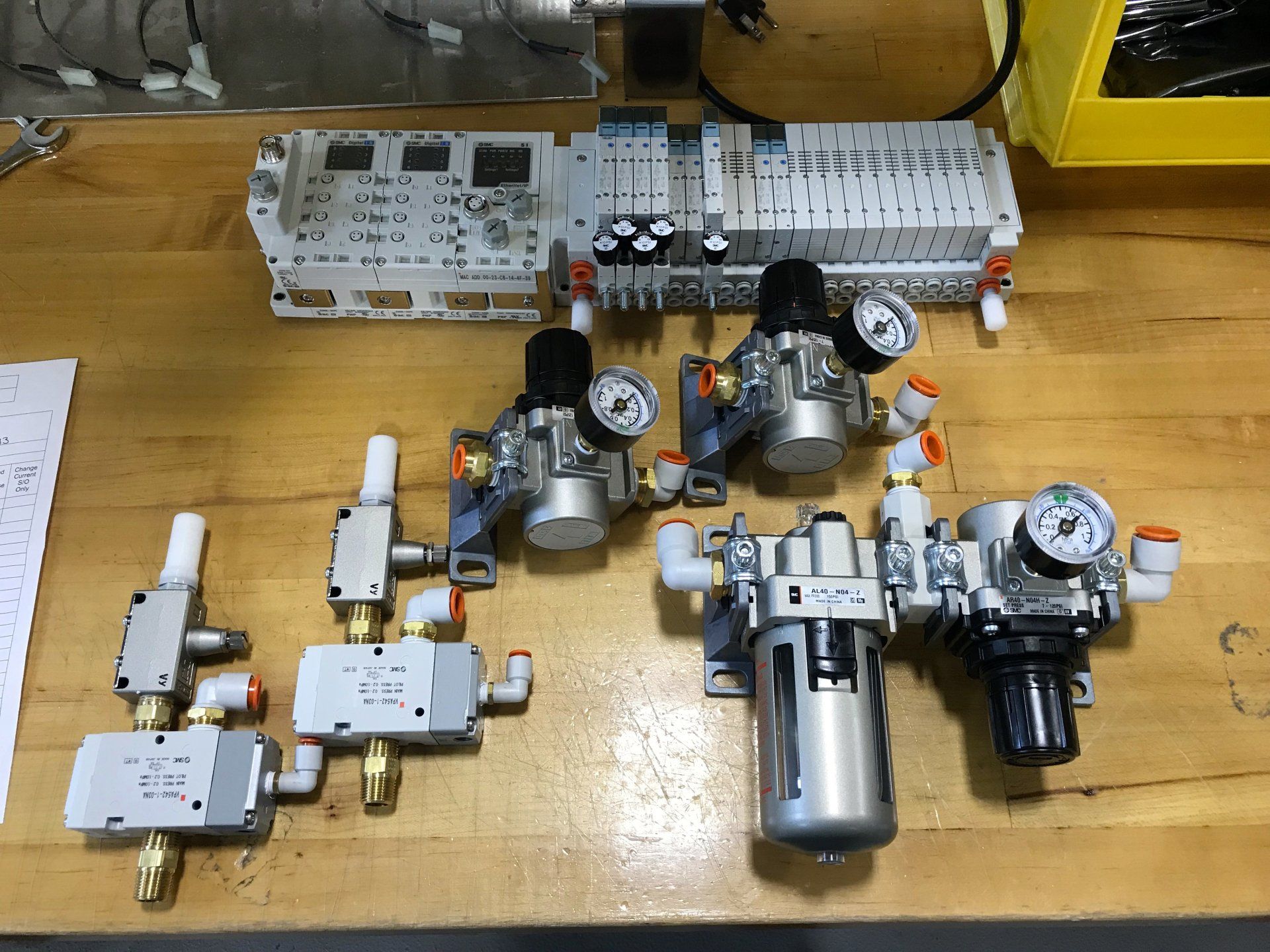

SMC Pneumatic Components and Product Selection

Our partnership with SMC Pneumatics provides access to one of the industry's most comprehensive product lines, encompassing actuators, valves, air preparation equipment, and specialized components for demanding applications. As an authorized SMC distributor, we maintain substantial inventory of commonly specified components while providing rapid access to SMC's complete catalog for specialized requirements.

SMC pneumatic components offer proven reliability backed by extensive engineering resources and technical documentation. From compact cylinders for space-constrained applications to heavy-duty actuators for high-force requirements, SMC's product range enables us to specify optimal components for virtually any application.

Product categories we regularly specify and integrate include:

Pneumatic System Design and Engineering Support

Effective pneumatic automation requires more than assembling individual components. Our pneumatic system design services address the complete system architecture, ensuring proper air supply, appropriate sizing, and reliable control integration. We evaluate your compressed air infrastructure, calculate flow requirements, and design distribution systems that maintain consistent pressure throughout your operation.

Air preparation represents a critical element of pneumatic system reliability. Our engineers specify filtration, regulation, and lubrication equipment appropriate for your application requirements and component specifications. System documentation forms an essential component of our design services. We provide pneumatic schematics using industry-standard symbols, installation drawings showing component locations and mounting requirements, and comprehensive bills of material with manufacturer part numbers.

Application-Specific Pneumatic Solutions

Our experience spans diverse industrial applications, each presenting unique pneumatic design challenges. Food and beverage processing operations require stainless steel actuators, FDA-compliant materials, and designs that withstand frequent washdown cycles. Pharmaceutical manufacturing demands cleanroom-compatible components and validation documentation. Packaging machinery requires high-speed actuation with precise position control.

Material handling applications benefit from pneumatic solutions offering rapid acceleration, soft landing capabilities, and adjustable speed control. Assembly automation applications leverage pneumatic advantages in force control and compliance. Process control applications utilize pneumatic actuation for valve operation, damper control, and material flow regulation.

Installation Support and System Commissioning

Our commitment to project success extends beyond design and fabrication to include installation support and system commissioning assistance. We coordinate with your installation contractors to clarify mounting requirements, confirm air supply specifications, and address questions that arise during installation.

System commissioning services include verification of proper component operation, adjustment of speed controls and pressure settings, and confirmation of safety interlock functionality. Training services help your maintenance team understand system operation, recognize common issues, and perform routine maintenance activities.

FAQs

What pneumatic/vacuum brands do you carry?

We're authorized distributors for SMC Pneumatics, Camozzi, Elmo Reitschle, and other leading manufacturers. We maintain inventory of common components and can source specialized products quickly through our supplier partnerships.

How do I size pneumatic components for my application?

Our engineers help you size cylinders, valves, and air preparation equipment based on your force requirements, stroke length, cycle time, and environmental conditions. We consider factors like load, speed, accuracy requirements, and operating pressure to ensure optimal performance.

What causes slow or erratic cylinder movement?

Common causes include insufficient air pressure, leaking seals, lack of lubrication, undersized valves or piping, contaminated air, or incorrect pressure regulation. Our engineers can diagnose your specific issue and recommend solutions.

How do I prevent moisture and contaminants in my pneumatic system?

Install proper filtration, regulation, and lubrication (FRL) units at strategic locations. Use air dryers to remove moisture from compressed air, replace filter elements regularly, and implement drain traps at low points in the system. We help design air preparation systems that protect your equipment.

What pressure should I run my pneumatic system at?

Most industrial pneumatic systems operate between 80-100 PSI, though optimal pressure depends on your specific application. Higher pressure increases force and speed but also energy consumption and wear. Our engineers help you determine the optimal operating pressure for efficiency and performance.

Can you design complete pneumatic systems or just supply components?

We provide both. Many clients purchase individual components for maintenance, while others need complete pneumatic system design including compressor sizing, distribution system layout, actuator selection, and control integration. We tailor our support to your needs.

How often should pneumatic components be replaced?

Component life varies based on application and operating conditions. Cylinders typically last several million cycles with proper maintenance. Valve life depends on cycle frequency and air quality. We help establish preventive maintenance schedules based on your specific equipment and operating conditions

Do you provide pneumatic system troubleshooting support?

Yes, our engineers assist with diagnosing air leaks, pressure problems, valve issues, cylinder failures, and control problems. We can visit your facility or provide remote troubleshooting guidance based on your specific situation.

Can you convert hydraulic systems to pneumatic operation?

In some cases, yes—particularly for lower force applications. Our engineers evaluate your force requirements, cycle times, precision needs, and environmental factors to determine if pneumatic conversion is feasible and cost-effective for your application.

Request for Quote

Get detailed specifications for your pneumatic system project. We provide comprehensive quotes including component specifications, design services, and complete project scope.