Flow Meter Offers Precision and Reliability for Hydrogen Applications

Hydrogen has become increasingly important in industries like energy and transportation, necessitating accurate, reliable measurements of hydrogen flow. Proper measurements go a long way toward improving safety and efficiency in these applications — especially in high-pressure dispensing stations.

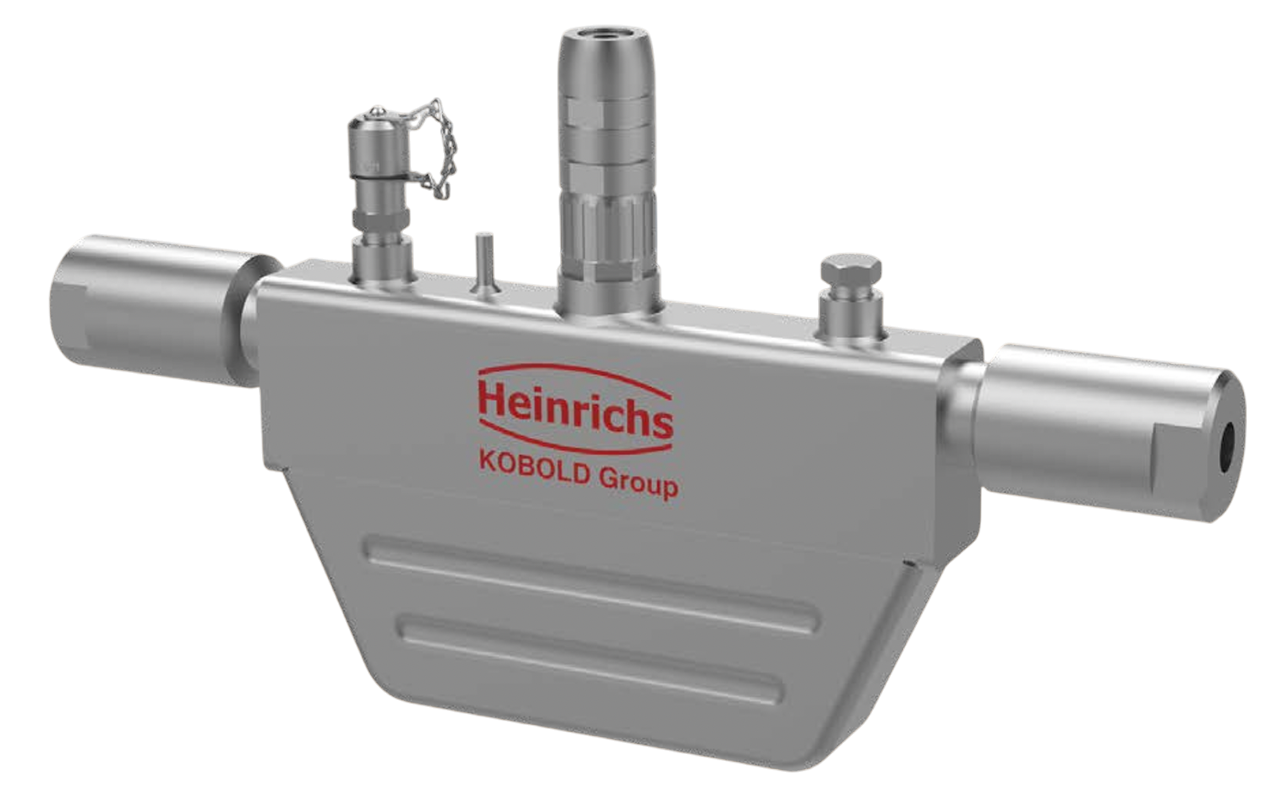

KOBOLD engineered its TMU-W Coriolis Mass Flow Meter specifically to meet these demands, offering exceptional performance for hydrogen filling applications up to 1,000 bar.

Engineered for High-Pressure Hydrogen Dispensing

Hydrogen filling stations require extremely high zero-point and long-term stability during the fueling process. To meet these requirements, the TMU-W incorporates a specialized design, ensuring the highest possible stability and unrivaled measuring accuracy.

To accomplish this task, KOBOLD designed this dual-pipe sensor system with special materials and used many sophisticated engineering methods like finite element method (FEM), computational fluid dynamics (CFD) and fluid-structure interaction (FSI).

Key technical specifications of the TMU-W include:

- Accuracy: 0.5% of actual flowrate and zero-point stability for gas.

- 6MF 9/16-18 UNF and optional 1/2" NPT (f) or Hofer 7/8" connections.

- Wetted parts — constructed from 316TI/1.4571 stainless steel.

- Temperature range: -40° to +80°C (ambient) and -50° to +100°C (process).

- Ingress protection: IP67 (EN 60529) / NEMA 6.

- May be used with UMC4 transmitters.

The TMU-W also holds several important certifications for use in hazardous environments and for metrological accuracy, including:

- ATEX, IECEx and UKCA: II 1/2G Ex ia IIC T2...T6 Ga/Gb.

- NEPSI: Ex ia IIC T2...T6 Ga/Gb.

- Available OIML R139:2018.

- SAE J2601 for hydrogen refueling stations.

To learn more about the TMU-W,

visit KOBOLD’s website.